Big Boost to the Solar Panel Industry Promised by Thin Wafer Technology

2011 was a long, dark year for solar cell manufacturers who faced dwindling global demand and crippling price reductions. However, new innovations to the wafer production process announced this month show promise of a bright 2012.

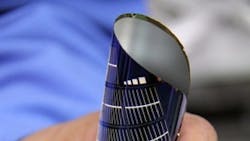

Within days, two competing solar panel manufacturers -- industry leader Silicon Genesis and newcomer Twin Creeks Technologies -- announced some exciting new, atomic-level production processes that are reported cut solar panel wafer thickness by up to 90 percent. This could be just the boost the industry needs to reclaim its momentum in the alternative energy race.

"We believe that the solar industry's severe pricing pressure further strengthens the proton beam-induced wafering approach," said Francois Henley, Silicon Genesis president and CEO. "We believe the benefit of using our technology will significantly cut the cost of making high-efficiency solar cells, allowing the PV industry to reach unsubsidized grid parity years ahead of expectations."

Twin Creeks Technologies

Twin Creeks Technologies' new Hyperion 3 wafer production system offers similar benefits, says the company. It uses hydrogen atoms as a scalpel to slice ultra-thin monocrystalline wafers down to a miniscule 20 microns.

"The thickness of wafers today is based on wafer slicing capabilities and the handling requirements for device processing," explained Dr. Siva Sivaram, CEO of Twin Creeks. "In reality, only the very top layer of a substrate plays and active role in generating energy or transmitting signals -- the rest is wasted."

"By eliminating excess material," he said, "we will help solar manufacturers produce modules that compete with grid power and open up new markets for chip makers."

By reducing the amount of silicon required in solar modules, the new systems add new efficiency and cost savings all across the silicon wafer value chain, said the company. Now manufacturers won't require as many saws, furnaces, and crystal pullers to produce the same amount of wafers, thereby saving money through every phase of development.

This is the deciding factor, explained Lux Research Analyst, Fatima Toor: if manufacturers want to compete today, they must find a way to create cost effective products.

Cost-Effective Products

"In the solar industry," she says, "the main metric is dollars per watt. So you have to produce watts."

This is especially critical right now. To stay afloat as global oversupply brought down prices last year, manufacturers had to dig ever deeper into their profit margins. If these new wafers can deliver what they promise, it may be enough for companies to more profitably produce wafers and take advantage of resurging customer demand.

Along these lines, things look rather promising for the new thin wafer design. According to Twin Creeks, the new process will initially reduce solar cell costs to under 40 cents per watt in commercial scale volume production, with prices expected to fall thereafter. This may be enough to help the solar industry reverse its trend of declining demand and market oversupply and see the uptick in demand Toors expects in 2012.

About the Author

Travis M. Hessman

Editor-in-Chief

Travis Hessman is the editor-in-chief and senior content director for IndustryWeek and New Equipment Digest. He began his career as an intern at IndustryWeek in 2001 and later served as IW's technology and innovation editor. Today, he combines his experience as an educator, a writer, and a journalist to help address some of the most significant challenges in the manufacturing industry, with a particular focus on leadership, training, and the technologies of smart manufacturing.