Bridging the Information Gap Between the Aging Workforce and Gen-Y's Digital Natives

Highlighted by the U.S. Bureau of Labor Statistics, in 2012 the average U.S. manufacturing worker’s age was 50 years old and half of the workforce was 10 to 15 years away from retirement. Alongside the younger generations’ aversion to “outdated” or “dirty” manufacturing careers, this growing cultural disconnect has been the topic of discussion in executive meetings across the country. Attracting fresh talent out of college is only part of the challenge. An additional -- and equally major concern -- regards the massive amount of human capital that is at risk of exiting manufacturing operations forever, only to spend its summers in the North and winters in Florida. That said, how do companies ensure that knowledge is captured and transferred to the next generation effectively?

Despite the use of modern IT and automation technologies, which are actually enabling a resurgence of U.S. manufacturing competitiveness and attractiveness, it is still unclear whether or not the generational lapse will persist. Time will tell. For now, this disconnect introduces a number of factors that could both directly and indirectly impact long-term business performance. The idiosyncrasies of each job role that keep operations running smoothly are at risk of being lost. On the manufacturing shop floor, for instance, these may include exception processes, which are unique situations requiring adjustments to production that cannot be planned for. Or escalation policies, tacit processes developed through experience where plant operators collaborate with other departments and notify their supervisors to take action in the instance of a particular process deviation. It is imperative that this type of “tribal knowledge” and experience is captured rather than slowly disappearing.

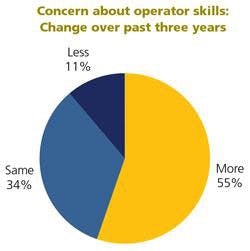

Vital knowledge exiting the manufacturing environment is a very real challenge. Julie Fraser, independent advisor and MESA outreach director, highlighted this in a recent article, where she shared data from a MESA sponsored survey of manufacturers and producers. She said, “Manufacturers are more concerned than ever about the skills of their plant employees -- both operators and supervisors.” The data shows that 55% of respondents were more concerned in 2012 than they were three years prior.

Although the aging workforce raises concerns in manufacturing, the challenge of securing intelligence is felt across a broad set of industries. Insurance and health care, among others, also have high proportions of older workers. Process-heavy and burdened by dynamic regulations, it is often the case that these industries require more than the existing human capital management capabilities that are found in most of today’s ERP solutions. Many organizations have already begun undertaking initiatives to consolidate and archive existing intelligence into document management systems that capture and organize standard operating procedures as best practices. Some have gone a step further, globally standardizing processes and capturing them with business process management or workflow software that ensures consistency of procedures.

As is the case with manufacturing and other business environments alike, enterprise software has been integral to not just preserving intelligence, but enabling real and continuous improvements over time. With ERP as well as manufacturing operations management software, which is more specific to the plant floor, companies can transform massive amounts of operations and performance data into knowledge and insights. Likewise, Internet technologies have made their way deep into many businesses, including manufacturing. Connectivity is rapidly progressing into the “Internet of Things,” which is and will enable even the smallest of devices to generate information and connect to people and other technologies. The resulting communicative and collaborative impacts to traditionally disjointed systems are key to overcoming the information bounds that have limited large, globally distributed organizations in the past, and are playing a significant role in preserving intelligence today.

The adoption of technology in support of any business is an evolutionary process. Some companies are at the height of IT maturity, investing in today’s emerging Internet, cloud-based, and mobile solutions, while others are still in the incipient stages of moving from paper to software. Those companies that are ahead of the curve have been taking advantage of not just the ability to chronicle intelligence over time with enterprise software, but also to streamline and enforce processes where possible. Circling back to the example of the manufacturing shop floor, production execution software used in combination with industrial automation systems has been leveraged to capture many traditionally manual processes and then infuse automation capabilities to virtually eliminate the risk of human error, while simultaneously increasing organizations’ productivity and competitiveness.

At the 2013 IndustryWeek Best Plants conference, one manufacturing executive described his company’s experiences with software and automation quite succinctly. The manufacturer strives to take humans out of the “dumb, dirty, and dangerous” jobs by using automation and software, thereby elevating its production personnel to focus on higher value-add activities. This approach certainly speaks to the transformation of manufacturing jobs into higher-skilled, technical, and production professionals, and this message needs to be clearly communicated to the next generation of potential manufacturing workers. It also highlights the efforts being taken to approach knowledge flight digitally. The adoption of such technologies is expected to only become more widespread as a sustainable knowledge management enabler over time.

Be it manufacturing, insurance, finance, health care, utilities, or another industry, the jump from fractured “tribal knowledge” or local processes to enterprise-level solutions that take advantage of modern Internet and software technologies is where the most benefits to intelligence are being experienced. Once the knowledge housed within individuals is systemized, that information acts as the foundation for identifying ongoing improvement areas, and then the enterprise applications help to communicate and enforce those processes and improvements globally.

The workforce in manufacturing and other industries may be aging, but if today’s technology is employed correctly, the intelligence that is at risk of being lost may not skip a beat. If fact, it promises to become even more powerful, while simultaneously making jobs in these industries ever more exciting and attractive to this generation of digital natives and those to come.

Mark Davidson is a principal analyst at LNS Research, covering the manufacturing operations management software space. Davidson has over 35 years of experience working with automation and information technology-based products and services -- in the areas of strategy and business planning, corporate M&A, new business development, sales and marketing, product line management, and internal/external corporate communications for B2B. He can be reached at [email protected].