An Intro into Generative Design

Humans are capable of great things when it comes to design. But nature, many would agree, is the greatest designer of all. Evolution has, over billions of years, perfected the animal and plant species that populate the planet, discarding less than optimal designs in favor of those that can survive and thrive.

What if evolutionary design could be mimicked using science-based methods? And what if that process could be sped up to be completed in minutes and seconds instead of years or eons? This has become possible thanks to generative design, which uses machine learning to circumvent the evolutionary approach and cut right to the optimal form.

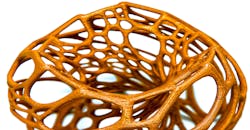

In generative design, an engineer will input a certain set of parameters—such as size, weight, manufacturing method, and materials—into the software. The software will then generate multiple design suggestions based on the parameters, offering the engineer a wealth of options for virtual testing and 3D printing. These options often include unconventional geometries that a human designer would likely never come up with – geometries that perform better than their more conventional counterparts.

In competitive fields such as the automotive and aerospace industries, generative design helps engineers to achieve objectives such as minimizing part weight, maximizing stiffness, reducing cost and optimizing material usage. The use of generative design can reduce part weight from up to 30% using traditional manufacturing to 70% using additive manufacturing. It also allows for innovation beyond that which can be achieved with the human mind alone.

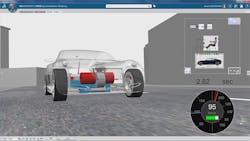

Today’s software tools have the capability of bringing together generative design, manufacturing simulation and virtual testing in a model-based seamless workflow. This saves additional time for designers and engineers, allowing them to quickly try out different designs and make changes in one single process. Disciplines that previously existed in silos can be brought together, enabling scalability and collaboration among users across an entire enterprise. Traditional CAD is moving away from Computer Augmented Design to Cognitive Augmented Design, in which cobots are creating unimaginable shapes.

A great deal of generative design technology exists today. These engineering tools generate optimal design concepts while respecting functional requirements and specifications. The software captures the best practices from a previously disjointed process and reduces the amount of time needed for engineers to identify new shapes that can maximize their business needs.

These fully integrated solutions present a unified interface for modeling, simulation and optimization, which is ideal for mechanical designers and engineers. Users need not be experts to use the software, as it is designed to be used by a wide range of people for a wide range of projects, including both traditional and additive manufacturing.

Generative design is becoming a big part of the technology shifts known as the Factory of the Future and Industry 4.0. More and more companies are seeing the benefits associated with automation and data exchange in manufacturing technologies, and subsequently seeing the same benefits and principles for design and simulation in generative design. Companies in the automotive, aerospace, healthcare and consumer goods industries are taking advantage of what generative design has to offer from lattices to organic shapes, with major manufacturers such as Airbus using the technology to optimize their planes.

While generative design is ideal for the complex machinery and parts, it can also be used to design something as simple as a chair or composites tooling. There are virtually no limits to what generative design can create. With its basis in the designs of nature, generative design is almost a representation of design coming full circle. Humans have made great advances in what they can create over the centuries, but for everything our technology has accomplished, it has come back to the oldest form of design of all: evolution.