Universities’ New Machine Learning Tool Improves Additive Manufacturing

Using machine learning to ensure that the pieces of an aircraft fit together more precisely -- thus cutting assembling and testing time-- is one of the users behind new technology being developed by researchers at Purdue University and the University of Southern California.

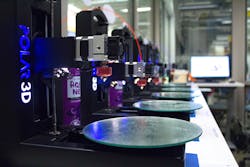

“We’re really taking a giant leap and working on the future of manufacturing,” said Arman Sabbaghi, an assistant professor of statistics in Purdue’s College of Science, who led the research team at Purdue with support from the National Science Foundation. “We have developed automated machine learning technology to help improve additive manufacturing. This kind of innovation is heading on the path to essentially allowing anyone to be a manufacturer.”

The technology addresses a current significant challenge within additive manufacturing: individual parts that are produced need to have a high degree of precision and reproducibility. The technology allows a user to run the software component locally within their current network, exposing an API, or programming interface. The software uses machine learning to analyze the product data and create plans to manufacture the needed pieces with greater accuracy.

“This has applications for many industries, such as aerospace, where exact geometric dimensions are crucial to ensure reliability and safety,” Sabbaghi said.

The researchers have developed a new model-building algorithm and computer application for geometric accuracy control in additive manufacturing systems. “We use machine learning technology to quickly correct computer-aided design models and produce parts with improved geometric accuracy,” Sabbaghi said. The improved accuracy ensures that the produced parts are within the needed tolerances and that every part produced is consistent and will perform that same way, whether it was created on a different machine or 12 months later.

Sabbaghi said the Purdue technology also allows users to create complex designs that would not be possible with traditional manufacturing processes.

Their work aligns with Purdue's Giant Leaps celebration as part of Purdue’s 150th anniversary. The researchers are working with the Purdue Office of Technology Commercialization to patent the innovation, and they are looking for partners to continue developing it.

About the Author

IW Staff

Find contact information for the IndustryWeek staff: Contact IndustryWeek