In the past year, there have been few topics as pervasive in the industrial community as the subject of environmental initiatives. But which industries' supply chains are actually leading the way? Are the benefits tangible (either immediately or long-term), or is this a matter of corporate responsibility? And if a company is looking to get started with green supply chain strategies, what types of resources might be necessary and where's the best place to start? These are the questions the Supply Chain Consortium sought to answer in a recent Hot Topic survey. Some of the results were surprising:

There is no single industry leading the environmental supply chain initiative.

While there are individual companies clearly embracing the leadership role in this area, the survey finds that each of the companies across industries has multiple competitors that have only recently begun "green" initiatives. And still others report having no formal program whatsoever. In fact, the numbers are generally consistent across all categories: 20% of respondents have had a formal environmental program in place for more than 3 years, 40% have begun a program within the last year, and 40% do not have one.

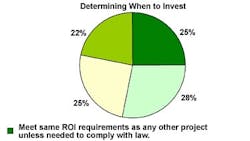

There is no consistent policy for ROI thresholds.

When asked to characterize their company's return on investment requirements for environmental initiatives, respondents were almost perfectly split (Figure 1).

Figure 1. Participants' Investment Requirements for Environmental Initiatives

Still, two classic supply chain core competencies -- minimizing total transportation and waste elimination -- are the most commonly-sited types of environmental initiatives. Somewhat surprisingly, survey respondents report that three core aspects of the larger green initiative -- water conservation, reduced commodity consumption, and re-usability -- are the least likely initiatives to receive consideration. This would seem to indicate that the "green" companies remain interested in the type of savings that resides in the local bank (Figure 2).

Figure 2. Participants' Decision Factors for Implementing Green Initiatives

But it's not just about the money, either.

According to the survey, companies are more likely to begin an environmental initiative to improve brand image, achieve regulatory compliance, or satisfy customer expectations than they are to optimize logistics flows or reduce manufacturing costs (Figure 3).

Figure 3. Participants' Benefits of Green Initiative Implementation

Organizations appear too internally focused.

Whether your company is just embarking on an environmental supply chain initiative or merely trying to maximize the potential impact, one of the best opportunities available today is to team up with supply chain partners to identify and take advantage of mutual prospects. Nearly 1 in 5 Consortium survey respondents report that all active environmental initiatives are 100% internal. Only 56% of the companies are attempting to collaborate with vendors, while less than half say they are working with customers, carriers, or third-party logistics service providers.

Personnel and Budgetary Considerations Count.

For those companies that boast a formal, environmental supply chain program, 31.1% have a full-time individual dedicated to green initiatives, while 28% state that they have an entire department. These companies specifically allocate an average of 5.1% of their supply chain budget to environmental initiatives, with the range being between 1% and 15%. As pressure from the global community increases, these numbers are expected to trend upward.

The Bottom Line: It is Not Too Late.

Green supply chain initiatives are receiving dedicated resources and yielding tangible results -- environmentally and financially -- across all industries. But if your company hasn't begun the process in earnest, you are not alone and you are not too late.

When identifying initiatives, it pays to look for traditional supply chain efficiencies that also carry environmental benefits, but companies should not hesitate to approach vendors, customers, and carriers about collaborative projects. If you are interested in seeing how your company stacks up or would like to receive the Supply Chain Consortium Hot Topic Report, go to www.supplychainconsortium.com/IWsurvey and take the survey. Once results have been tallied, the Consortium will send participants an updated version of the report.

While many companies do not have formal programs, the Consortium survey reveals that several companies are leading the pack in implementing customized solutions for greener supply chains. A few of the solutions that were identified as yielding tangible results are:

- Joining the U.S. Environmental Protection Agency's (EPA) SmartWay Transport Partnership, which is an innovative collaboration between the EPA and the freight industry that increases energy efficiency while significantly reducing greenhouse gases and air pollution.

- Installing Alternative Power Units (APUs) in Private Fleets for heaters, air conditioners, etc., in sleeper units. One company reports an 80% reduction in engine idle time after installing APUs.

- Installing energy efficient lighting. After replacing lighting at all plants and distribution centers with energy efficient alternatives, one company reports a payback time of less than 2 years.

- Engaging in proactive recycling. One beverage company notes contracting with a company specializing in recovery of recyclable materials to build a plant that will specialize in making food-grade, highly-recyclable bottles out of previously used resources. The facility will be able to make approximately 2 billion bottles per year using essentially no new raw materials.

- Near-sourcing air-intensive components. Another company in the beverage industry receives plastic bottles in compact, un-blown, "test tube" format. The bottles are blown into shape on-site, reducing the number of truckloads required to deliver bottles to the plant by 90%.

- Driving environmentally-friendly company cars. After switching over its fleet of company cars, one company's sales team only drives Toyota Prius hybrids.

- Printing two-sided. One company mandates the use of two-sided printing, a feature commonly available on many late-model laser printers.

- Efficiently routing and loading transportation. Multiple companies reduce out-of-route and empty miles, increase cube utilization, and emphasize multi-stop shipments.

- Working with builders for a green facility. If presented with the opportunity to build a new facility, work with architects, contractors, suppliers, and every level of government to ensure the facility is as environmentally friendly as possible and that all available grants and tax advantages are being realized.

- Implementing Specific, Measurable, Achievable, Relevant and Time-bound (S.M.A.R.T) Environmental Objectives. One world-class participant has the following objectives to complete by 2015: 25% carbon footprint reduction, 25% waste reduction, 100% of paper originating from sustainable sources.

These are only a few examples that have been implemented as environmental projects. More options are becoming available as maturing technology and rising energy costs combine to make a greater variety of initiatives feasible.

Chris Ferrell is Associate Director of the Supply Chain Consortium, the premier source for supply chain benchmarking and best practices knowledge. With more than 180 participating retail, manufacturing and wholesale/distribution companies, the Consortium sponsors a comprehensive repository of 17,000-plus benchmarks complemented by search capabilities, online analysis tools, topic forums and peer networking for supply chain executives and practitioners.

Interested in information related to this topic? Subscribe to our weekly Value-chain eNewsletter.