Expansion Management: Stable Workforce + Stable Economy = Success for Winnipeg

How does a city of 778,000, located right in the middle of North America retain its competitive position in manufacturing? For Winnipeg, Manitoba its reliable workforce in combination with a stable economy is proving to be quite attractive to manufacturers. And to top it off the city has the coveted advantage of a strong public-private partnership that is backed by investment.

“We have a stable cost structure and a stable workforce,” explains Don Boitson, general manager of Magellan Aerospace, a Canadian manufacturer of aerospace systems and components. The company, which has called Winnipeg home for over 50 years, is constantly evaluating where and how to grow.

Growing, as manufacturers know all too well, requires a pipeline of talent with specific skills. In Winnipeg the skilled workforce is the direct result of a partnership with educational institutions. “Our universities and technical schools understand that retraining is essential so skills are kept up-to-date,” says Boitson. “They work with us to develop programs that meet our needs.”

In fact the government, both at the provincial and federal level, goes a long way to make sure that employers’ needs are being met. One especially appealing program to Magellan allows students to train on-site. This set up is a little unusual as often an employer provides equipment to a community or technical college which in turns handles the training.

“This program really teaches student what the game looks like,” explains Paul Soubry, CEO of New Flyer. New Flyer manufactures heavy-duty transit buses for both Canada and the US. In fact Winnipeg is the largest bus producer in North America.

What’s unique about the workforce is that it’s self-contained. “We grow our own workforce, rather than import it,” says Soubry. “With our variety of educational facilities we can produce employees from the shop floor to engineering to leadership positions.”

Once embedded in the city, which historically is strong in manufacturing, employees don’t leave. “Although a small city, we have a big-city mentality,” says Soubry. “We are culturally diverse and offer an affordable lifestyle. Consequently we have very high retention rates.”

The manufacturing workforce is a crucial part of the city’s economic health accounting for 10% of all employment and 12% of the city’s GDP. There are 1,300 manufacturing companies that employ 42,000. The sector is showing strength with a projected increase of 3.5% this year and 4% in 2015.

Winnipeg's Value Proposition

“The three key elements of why the city’s value proposition is so strong are our low energy costs, our skilled workforce and our favorable tax structure,” explains Greg Selinger, Premier of Manitoba.

Selinger has some strong facts to stand on. The city was ranked #1 in overall cost competitiveness in the North Amercan Midwest by KPMG in March 2014.

A number of factors contribute to that ranking. On the energy side, Winnipeg has the lowest published electricity rates in North America for mid-sized and large consumers. And 99% is hydroelectric energy.

Going back to 2009, the province was the only one in Canada to not have negative GDP growth. In terms of labor productivity (measured from 2007-2012) the province ranked the highest in Canada.

On the tax side the province has the lowest overall tax rate in the G7. To support manufacturing, R&D and innovation there are a number of tax breaks.

“Our Manitoba Research & Development Tax Credit, at 20%, is very favorable,” Selinger points out. “And this is available to companies at all stages of development -- from creation to production.”

Aiding R&D are strategic policies involving public and private efforts.

Some programs include:

Industrial Research Assistance Program: Provides support to small and medium-sized enterprises in Canada in the development and commercialization of technologies.

Natural Sciences and Engineering Research Council of Canada: Assists and provides financial support to universities, colleges and other organizations to encourage academic-industrial collaboration.

University of Manitoba Technology Transfer Program: Makes research available to partners with no financial commitment until the company itself starts making money from the technology.

Red River College Industry Partnership Programs: Provide industry workforce training and financial benefits to both industry and RRC, ex: Centre for Aerospace Technology and Training & Centre for Non-Destructive Inspection.

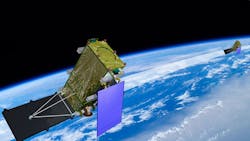

In addition to those programs, research institutes have been created. In fact last month, Magellan Aerospace announced it had formed a partnership with the University of Manitoba to establish an advanced satellite integration facility in Winnipeg. Both the company and the university will provide funds to research, develop, construct and test satellite buses and components.

“We have a great system in Winnipeg where the government listens closely to what industry needs and makes sure there is collaboration to get things done," says Boiston. “It’s a great pull system.”

It’s not only the new projects that receive funding. In July of last year, Selinger, speaking at New Flyer, announced additional support for the Vehicle Technology Center. It was formed in 2002 to support the heavy vehicle manufacturing sector, which includes New Flyer, Motor Coach Industries, and Buhler Industries. This sector represents 10% of the province’s exports and employs 6,500.

The research drawn from the Center assisted New Flyer which last month announced that its battery powered electric bus came into service in Winnipeg.

The electric bus was created as part of a consortium which includes the government of Manitoba, Manitoba Hydro, Mitsubishi Heavy Industries, Red River College and Winnipeg Transit. The company has sold 276 of these buses to the New York City Transit Authority.

Collaboration is front and center for New Flyer as well as other manufacturers. Soubry points to Canadian Manufacturers and Exports (CME) and Yes Winnipeg! as two particularly useful organizations. CME functions as a trade organization and actively promotes benchmarking across the variety of manufacturers. And Yes Winnipeg! has helped New Flyer secure the resources necessary to expand.

Bill Morrissey, CEO of Yes! Winnipeg, says the model of public-private partnership and collaboration has served the province well. “Collaborative efforts are a differentiator for this region,”he says. He cites the Manitoba Manufacturing Tax Investment Credit that provides a 10% tax credit for buildings, machinery and equipment as an incentive that has helped many companies. Also popular is the Co-op Education & Apprenticeship Tax Credit and Wage Subsidies that provides a 15% credit on wages, up to $5000 per apprentice per year.

“Creative investment strategies are also a hallmark of this city,” Morrissey says giving the example of Price Industries, a manufacturer of HVAC and distribution products, which last month received a $10 million repayable, interest-bearing loan secured under the Manitoba Industrial Opportunities Program. The funds will be used to expand manufacturing production as well as further funding for the Price Research Center North. The province will also contribute $1.5 million to train the workers needed for the expansion.

“Our commitment to our manufacturing community includes full wrap around support,” says Selinger. “With our model of 70% private funding matched with 30% public funding, our manufacturers are well prepared to compete globally.”