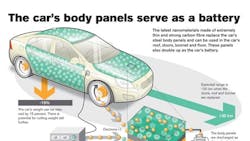

Electric vehicles might be the rage of automakers nowadays, but engineers continue to be undermined by the inefficiency of car batteries, which are immense in size, heavy and prohibitive in cost. Volvo is hoping to tackle all three problems in one technology breakthrough: a body panel capable of storing energy.

The automaker is working with the Imperial College in London on a materials development project with nine other European companies and institutes in creating a composite of carbon fibers and polymer resin that would store and discharge large amounts of energy quicker than any conventional batteries today.

Those carbon fibers aren't all that different than what is found in tennis rackets and fishing rods. But according to researchers, because the material doesn't use chemical processes, it recharges far faster than conventional batteries and has the potential to reduce the weight of the automobile by up to 15%.

The technology is still only in its infancy and according to Volvo and Imperial College the next challenge is finding a way to mass produce the carbon fiber blend. Volvo estimates that within the next three years, it will convert a vehicle's spare wheel recess into a composite battery.

"This is a relatively large structure that is easy to replace," says Volvo researcher Per-Ivar Sellergren. "Not sufficiently large to power the entire car, but enough to switch the engine off and on when the car is at a standstill, for instance at traffic lights."

Within a decade, the automaker estimates it could begin commercially producing the material for vehicle roofs and dashboards -- or for smaller objects, such as mobile devices and computers.

"The future applications for this material don't stop there," says Dr. Emile Greenhalgh, the project coordinator from the Department of Aeronautics at Imperial College London. "You might have a mobile phone that is as thin as a credit card because it no longer needs a bulky battery, or a laptop that can draw energy from its casing so it can run for a longer time without recharging. We're at the first stage of this project and there is a long way to go, but we think our composite material shows real promise."