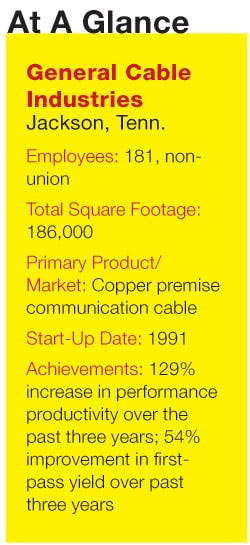

2013 IW Best Plants Winner: General Cable -- From Chopping Block to Award Banquet

Undergoing a cost-competitiveness feasibility study in 2008 was not comfortable for General Cable's Jackson, Tenn. plant. While the decision was made to keep the plant in operation -- and consequently invest more capital -- due to its high volume potential, a complete turnaround was ordered.

By 2012, victory was theirs. The plant was named the best plant in North America in the General Cable family and this year was named an IndustryWeek Best Plants Winner.

"Our plant was in dire straits in one of the toughest economic times ever. However, we knew we could get to where we needed if everyone was willing to make fundamental changes," explains Joseph Brown, plant manager. "We shut down the plant for a day, gathered all employees and launched our 'All In' program."

The All In program, signed by all employees, required concentrating on a few key areas, including safety and achieving first-pass yield quality, in order to exceed performance expectations. The culture shift to achieve these goals called for a workforce that was engaged, flexible and willinThe facility, which daily produces 25 million conductor feet of copper premise communication cable, also reorganized its production floor for cellular manufacturing. Cell members became responsible for safety, quality and tracking new metrics. Armed with green wrist bands that say "Consequence Thinking – Stop -- Think -- Plan," all associates take an Intro to Lean Training class.

Equally important as training is the talent management program, called "Altitude."

"Finding a comprehensive system to track training and coaching efforts was a way to aid our culture shift. It allows us to have positive touch points and demonstrate how important it is to be updated in our skill sets," says Brown. In fact this plant's program will be adopted at other General Cable plants.

The cellular structure, complete with a new cross-training and 5 Sigma program, formed the foundation necessary to continue current product production, attract a new line and bolster its PVC (polyvinyl chloride) pellet production line that supplies the plant, and other General Cable plants, with jacketing extrusion.

The benefits of these efforts have been plentiful. The plant has gone over 2,660,000 hours without a lost-time accident. Customer complaints have been reduced by more than 20% in each of the past four years. And, in 2011, the plant received the corporate Most Improved Quality award.

"All associates are quite proud of the fact that the facility has become the company's largest-volume and lowest-cost supplier of Category 5 riser premise cable," Brown adds. That pride is demonstrated quite clearly by a very large wall, called Walking Tall in Jackson TN, which every visitor must pass.

Pride cannot be overstated at this plant. During an explanation of some of the metrics that a specific cell was examining, one of the team members had trouble getting the data he needed so he worked after hours to create a system that provided the information. To hear him tell it, that was just a part of his job.

That attitude and dedication, more than any system, is why the plant has shown a healthy increase in performance productivity over the past three years.

Read more about 2013 IW Best Plants winners.

See the IW Best Plants winners at the 2014 IW Best Plants Conference.