From Gen Z to C-Suite: an Intergenerational Conversation on Innovation

Just as the doors of Generation Z’s future were flung wide open, the world tap-danced into the abyss. The year was 2020. Gen Zs were entering high school and college, starting internships and jobs, setting out on the path to real adult life. All that was put on hold because of COVID-19, of course.

Generation Z, whose eldest members are around 25, isn’t the only youthful cohort to have its formative years end abruptly (baby boomers had Vietnam to thwart their plans). But they are a unique group of young people, shaped by singular events.

Generation Now stories focus on challenges and opportunities facing industry as multiple generations of leaders take on responsible roles in manufacturing. The first piece ran in the spring of 2022 and won a national award for manufacturing business writing.

Stories include:

- Generation Now Leadership: Part 1, Falling Into Manufacturing at Smucker's

- Generation Now Leadership: Part 2, Fast-Track Training at Timken

- Generation Now Leadership: Part 3, Career Advancement by Design at Northrop Grumman

- Generation Now Leadership: Part 4, Co-op to Advanced Manufacturing Management in a Decade at Freudenberg-NOK

- Generation Now Leadership: Part 5, Finding Passion at Precision Plus

- Generation Now Leadership: Part 6: From Military to Manufacturing at Graphic Packaging International

- Generation Now Leadership: Manufacturing’s Next Generation Steps Forward

- From Gen Z to C-Suite: an Intergenerational Conversation on Innovation

They’ve watched family members endure crippling debt from the Great Recession and the student-loan crisis, randomly downloaded Duolingo on their parents’ iPhones to teach themselves basic Korean before the age of 3 and have had to come up with workarounds for things that should be straightforward, like having a prom or going to school every day to learn algebra.

Their formative experiences fostered creativity, practicality and the full embrace of technology—exactly the qualities that manufacturing needs in its workforce to MAKE IT in the future. But what manufacturing needs is not the point of this story. Manufacturing must figure out what Gen Z needs to desire and pursue a career in manufacturing, and to thrive and stay in manufacturing because their contributions are valued.

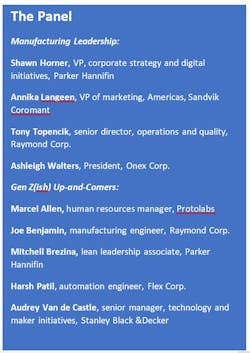

To get the debate rolling, IndustryWeek put together a Zoom conversation in February 2022 with nine manufacturing leaders, young and older, about how to create an innovation culture that’s truly intergenerational. To have an intergenerational culture, of course, you first must have actually have different generations that work for you, so our discussion also touches on how to attract, welcome and engage Gen Z in the workplace.

The 10 takeaways from our hourlong conversation were wide-ranging and illuminating, especially when the observations came from Gen Z participants. They hit upon some common themes around workplace culture, and the ways Gen Z workers think or work or innovate differently than older colleagues.

Manufacturers, take note: many wise-beyond-their years, ambitious potential employees are interested in what manufacturing has to offer, if you do the work to answer their questions, show them a path forward and listen instead of shut down.

1. Giving new hires a feel for the company requires more investment than showing them where the lunchroom is on their first day.

Remember the days when a corporation was a mysterious entity, its siloed-wisdom nuggets parceled out by some grizzled coworker when the mood hit? Well, they’re gone now. From day one on the job, the Gen Zs on our panel valued meeting, learning from and connecting with people in different roles and at different levels, and gaining a high-level view of the organization and how its discrete components unify.

Audrey Van de Castle, a self-professed “process nerd” and rising leader at Stanley Black & Decker declared that if the culture isn’t about openness and learning, she’ll leave. “I really value transparency and clarity in leaders,” she says. “I want to know why decisions are being made—especially if they’re affecting me—or even have a seat at the table.”

Mitchell Brezina, a recent Purdue University materials engineering graduate, chose Parker Hannifin for its leadership development program that schools recruits in different functions and opportunities at the company, “from quality to operations to lean,” and “from aerospace to motion controls.”

That high-level view is important. The scope of Parker’s manufacturing and the differentiation of its precision engineered components across 10 different segments can be difficult for an outsider—even an outsider who is studying engineering—to get a handle on. Brezina says the program, which has taken him to plants from California to New York, “has been a great opportunity to network and meet a whole lot of different people” as well as show him what career paths are possible.

2. Diversity, equity and inclusion must go deep.

DE&I ranks very high with Gen Z, and it’s not just about branding and/or recruiting—it is important through all facets of the company.

Van de Castle puts DE&I—“getting more women and minorities into the skilled trades, construction, manufacturing and all that fun stuff”—right up there with working with tools as a passion. She is the co-chair of Stanley Black & Decker’s Women’s Network employee resource group, and co-founded a second ERG, Women in Operations Network.

“Being able to live your truth and have that kind of social and empowerment angle in our day-to-day job, I think that’s really critical, and something that I really value,” she says.

Van de Castle didn’t join SB&D seeking to be a diversity champion, but the SB&D culture opened her to new interests around diversity that “made my experience much more fulfilling.” Even her lean manufacturing knowledge translates to her diversity work. When the Women’s Network EBRG identified that SB&D had few female operations leaders, the group’s next step was to “5 Why it” to determine a root cause. Their finding: Women are passed over or not even considered for early-career leadership roles, and become “stuck,” never making to the upper management track. Their action: developing a training program for hourly women with high potential that teaches communication leadership, how to manage a team and lean Six Sigma.

“We actually had a lot of women that were participating get promoted to supervisory positions during the program,” says Van de Castle. “[The company] was hungry for supervisors.”

Her EBRG work, she says, is “one of the things that has kept me here.”

3. Innovation flourishes when connected with purpose.

Gen Z is looking to be engaged differently, notes Marcel Allen, an HR leader at additive-manufacturer Proto Labs. They seek a strong purpose for their work and a clear idea of what’s ahead. “And that’s both before and during their employment,” he adds. If they’re not engaged or don’t feel the culture is a good fit, they have no qualms about leaving (see: The Great Resignation).

Through social media campaigns and awards programs, Protolabs has begun highlighting how other companies use its capabilities to “fill in the gap between production and prototyping.” A Cool Idea Award grant of $25,000 recognizes innovative external projects in education, sustainability, philanthropy and medical devices. A partnership with a YouTuber showed the world that Protolabs’ technology (a custom-designed pneumatic system) could make a thief-deterring “Glitter Bomb” more effective, and more awesome.

At SB&D, a partnership with startups at the Tech Stars incubator netted a machine oil “that’s compostable and very green and launched it at Home Depot,” tying purpose into a quickly realized successful product launch, says Van de Castle. At Parker, when Brezina was being recruited, the company’s focus on electrification and reducing greenhouse gases stood out, as well as its emphasis on collaboration and encouraging a diversity of ideas to be shared across teams. “Everyone’s opinions are valued in solving the problems that we’re seeing today,” he says.

Another place companies should be thinking broadly about purpose is in their acquisition planning, says Van de Castle. SB&D’s purchase of MTD, “a big, gas-powered outdoor equipment company” might seem like a risky move, she says, but Stanley excels at the electrification piece, so the focus is on “injecting our innovation and battery technology into it to make maybe a zero-turn riding mower that’s fully electric—and maybe even solar powered.”

4. Passions in work vs. personal life are no longer distinct.

The pandemic blurred lines between work and personal life—and that brought flexibility in completing tasks. “I really appreciate that,” says Van de Castle. “But, I also [appreciate] being able to blend the things that I’m passionate about when I’m not working—equality and diversity, and being able to use my company as a platform to help further that. And that I think is something that’s really fulfilling for anyone, but also especially the younger generations.” Social media can help with the blurring between work and the outside world, she advises. “Your employer brand externally really has to be present on social media. LinkedIn, and I think even TikTok is a good place to start getting into.”

5. Having a clear future yet being able to learn and try new things in the moment brings engagement and productiveness.

Gen Z is looking for “a culture of growth, innovation, learning and development, so they can see what’s next or ahead of them,” says Allen. Protolabs allows employees to collaborate widely and experiment with different approaches during their day—which fits with the dynamic nature of the business, “thousands of customers who all have different needs,” he says.

Joe Benjamin, a recent engineering graduate who started as a material attendant at Raymond and has since been promoted, craves learning new tasks and taking on responsibility. “I am now one year in manufacturing engineering,” he says. “I’ve taken on a solid role here. I’m helping support one of our assembly lines. I’m taking over from another one of our associates who is moving on to another discipline in that regard. And I’m very excited and happy with what’s going on right now. And excited to keep going forward.”

At Flex, automation engineer Harsh Patil says learning opportunities include regular group calls where subject-matter experts on certain topics share their knowledge with the engineering and operations communities all across Flex, around the world. “You can ask questions and get answers,” says Patil. Engineers and plant managers share their pain points in virtual tours of Flex factories across the globe, “and we can engage with the site leaders or even key stakeholders in that particular project.”

6. Structure without bureaucracy is the gold standard.

Manufacturing is all about process, and some Gen Zers yearn for process. Benjamin is among those devotees. “What really drew me to Raymond is how, although we’re a medium-sized company, how large our scale is and how we do things,” he says. “The logistics of how we carry out things is what really draws me in. I’ve always liked organization along the line and making sure things flow.”

Along with describing all their cool tech, manufacturers could benefit from playing up process with potential recruits. Patil previously worked at a manufacturing-tech startup, but he actually prefers Flex for the time-tested processes that are part of its culture.

“Since Flex is such a large and old organization, some things are very organized and structured,” he says. “That in itself helps a lot, especially with things like onboarding and task allocation.” The efficiency extends to innovation as well. “Once a problem is presented to us, we come up with solutions, develop solutions and also deploy those solutions fairly quickly, just like any startup could,” he says.

It’s important, however, not to confuse a structured culture with a command-and-control culture. A second-generation manufacturer, industrial furnace maker Onex Inc. chose to make the shift to what company President Ashleigh Walters calls “a continuous improvement structure,” where the hierarchy is flatter and everyone is encouraged to innovate.

“You’re not going to get a lot of innovation with a command-and-control style culture because you’ve got leaders or managers telling people what to do,” Walters says. “They’re not allowed think for themselves. For me, it was a real struggle and a real challenge to get people thinking for themselves because they have been told what to do for so long. So, we really use lean to develop problem-solving skills.”

Lean can not only provide structure, it can facilitate cross-generational collaboration. Raymond’s Tony Topencik, who has worked at the company 29 years and is now oversees operations and quality, says Raymond uses two TPS tools to bring shop-floor people together in intergenerational problem-solving: A Kaizen blitz to solve a challenging problem in a specific process area in two to three days, and a second activity that includes several weeks of planning, three weeks of execution and a week of follow up with high-performance team.

7. Digital must permeate the entire organization, not just shop floor processes.

Being digital-forward should extend to recruiting, training and business processes. “Filling out Excel sheets is just not something that we want to do in the long run,” Patil says of Gen Zs.

“In a lot of manufacturing, the methodology is, ‘If it ain’t broke, don’t fix it,’” says Van de Castle. “’I’ve been doing it this way for 30 years and using a pencil and paper to record this data. So that’s just what I’m gonna keep doing.’ And so, I can understand why to the younger generations, manufacturing is not attractive.

“When we’re hiring and training, our retention goes up when we’re using digital methods. So, by being digital forward, and using technology in these traditionally archaic-seeming spaces, that’s a way we’re able to attract the younger generations. I’m not going to go to a place that makes me fill out a paper application. It’s just not going to happen, right?”

8. Asking questions is a good thing.

Annika Langéen, who directs sales for the Americas for global cutting tool company Sandvik Coromant, says that Gen Zs characteristic inquisitiveness and openness to new ideas should be embraced as an important part of innovation. They dare to question and are open to sharing their opinions, “and that is a really great contribution to the organization,” she says. “So even though they may come new into both the industry and the company, they put the questions out there, and that’s really powerful.”

Benjamin is one of those super-inquisitive Gen Z recruits. Two years ago, when he took his first grown-up job at Raymond, he wanted to “learn about all of our trucks that we make, how they function.” A community college student at the time, he worked his way into helping test vehicles, asking questions that brought in his engineering studies. “Maybe it was a little unorthodox every now and again, for they just want a simple test,” he says. “But I was always curious, like, ‘If we did this, how would it affect that?’”

He was also curious about his career trajectory. Raymond leaders made it known they liked to hire from within, “and I just let my managers know, ‘Hey, I’m still interested in staying with this company and using more of my background and my education to help further the cause here.’

“And it wasn’t too long after that, someone saw that I was very proactive in everything that I was doing, going above and beyond,” he says. “I was always looking at things from a systems perspective: ‘When we put these two bolts here, let’s take it a step back. What happens if we apply it this way, or if the torque is applied in this manner?’ Giving them a wide-angle perspective rather than that focused view is something that I enjoy doing.”

Benjamin’s inquisitive mind, says Topencik, is “a welcome feature that we’re really seeing and enjoying from the Gen Z associates.”

9. Shake off the old cliches already.

Several younger panelists said they don’t understand why manufacturing doesn’t trumpet its high-tech even more. Industry leaders are overconcerned with overcoming the “dirty, dark and dangerous” image, an old idea about manufacturing that their generation isn’t even aware of.

Brezina remembers being flat-out puzzled when an older colleague mentioned manufacturing’s behind-the-times reputation. “Maybe that’s the case where you’ve got old machines or don’t invest in something,” Brezina says. “But I think there’s a newer push for that innovation, where we’re getting out of the ‘if it ain’t broke, don’t fix it’ mindset. We’re pushing the boundaries and looking for new ways to solve our modern-day problems.”

Walters, an engineer by training, plays up the excitement of equipment and processes when she describes her company. Onex is not a dying old furnace manufacturer; it’s an employee-owned maker of epic, state-of the art machines and a servicer of fascinating older ones. “We’re at the beginning of supply chains for aerospace and defense,” she says. “We are building and servicing industrial furnaces that are either melting or forging specialty steels, alloy steels, that are going to be machined into your aerospace and defense parts for the most part.”

Benjamin notes that the fast-changing nature of technology has kept everyone hopping, including Gen Z, making cross-generational collaboration around technology even more important. “I guess we’re more adept at getting the answer faster than most or trying our best to get as much information from a lot of sources as fast as we can. But we’re now living with technology every minute, and it’s even moving faster than we grew up with. So, we’re keeping up.”

10. Part-time (and plant tours) can be a pipeline for recruiting people with new perspectives.

Walters observes that smaller manufacturers are waiting too long to reach out to Gen Z. “I think we all talk about going to the high schools to recruit, right?” she says. “That’s not a five-year plan. Eighth graders are your five-year plan.” It’s important to bring families in the community into the plant, “so they can see how fast the production is and talking to them about all the great things that you’re making and where they go in the world.”

This summer, with hiring difficulties, Protolabs experimented with loosening requirements around age and experience, lowering the cutoff to 15 years old for part-time work, creating customized cells for those younger workers around tighter safety requirements and providing them with mentors in a work-study-type program.

“What we found is, they are some of our most engaged individuals,” says Allen. “We have probably had 30 high schoolers coming through the program. It really has been another pipeline for us.”

When he was a teen, Allen “didn’t understand what it truly meant to work in manufacturing. I never would have thought to put too much time and attention into thinking how my products are made,” he said. “I just consumed them. So, introducing that at an early age, I think is very good. It’s going to be really critical.

“I think we can also be really proud representing this industry because I think this is one of the industries that can give most people fantastic opportunities and be relevant to them. We have so many opportunities here. So, where we really need to focus is, ‘How do we get the word out?’ You can enter this industry in so many different ways and immerse in the opportunities that we have. I think we are a little unique in that way.”

Senior Editor Laura Putre can be reached at [email protected], and editorial assistant Anna Smith can be reached at [email protected].

About the Author

Laura Putre

Senior Editor, IndustryWeek

As senior editor, Laura Putre works with IndustryWeek's editorial contributors and reports on leadership and the automotive industry as they relate to manufacturing. She joined IndustryWeek in 2015 as a staff writer covering workforce issues.

Prior to IndustryWeek, Laura reported on the healthcare industry and covered local news. She was the editor of the Chicago Journal and a staff writer for Cleveland Scene. Her national bylines include The Guardian, Slate, Pacific-Standard and The Root.

Laura was a National Press Foundation fellow in 2022.

Got a story idea? Reach out to Laura at [email protected]