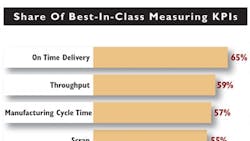

An Aberdeen Group survey of more than 400 manufacturers shows that top-performing operations depend on several key performance indicators (KPIs) to measure success. Respondents that report the most success also say they're integrating lean-enabling technologies with their ERP systems. Aberdeen distinguishes "best-in-class" manufacturers as companies that have achieved an average of:

- 95% on-time delivery;

- 91% throughput;

- 79% manufacturing cycle time reduction.

But manufacturers identified other KPIs that were critical to their operations (see chart). Aberdeen Group also asked manufacturers about the top market pressures they face. Respondents say their challenges include:

- the ability to reduce overall manufacturing costs -- 71%;

- using manufacturing as a competitive advantage -- 34%;

- achieving shorter lead times demanded by customers -- 32%;

- effectively dealing with demand uncertainty -- 21%;

- increasing complexity of manufacturing processes -- 18%;

- rising demand for more on-time and complete shipment -- 11%.

About the Author

Jonathan Katz

Former Managing Editor

Former Managing Editor Jon Katz covered leadership and strategy, tackling subjects such as lean manufacturing leadership, strategy development and deployment, corporate culture, corporate social responsibility, and growth strategies. As well, he provided news and analysis of successful companies in the chemical and energy industries, including oil and gas, renewable and alternative.

Jon worked as an intern for IndustryWeek before serving as a reporter for The Morning Journal and then as an associate editor for Penton Media’s Supply Chain Technology News.

Jon received his bachelor’s degree in Journalism from Kent State University and is a die-hard Cleveland sports fan.