"Freight bidding can be a time-consuming endeavor that is disruptive to the supply chain," admits Chris Ferrell, principal with supply chain consulting firm Tompkins Associates, "but bidding is necessary to ensure that you are receiving competitive rates and quality service." Based on a recent survey conducted by the Supply Chain Consortium, Ferrell offers the following best practices for supply chain executives involved in freight bidding.

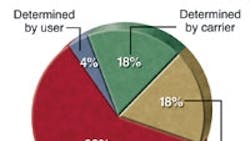

Percentage of companies who determine lane bundles in freight bids:

Source: Supply Chain Consortium

Allowing a carrier to bundle a group of lanes that complements its current portfolio is more likely to yield a lower total bid than the sum of the individual lanes.

See Also

About the Author

Dave Blanchard

Senior Director of Content

Focus: Supply Chain

Call: (941) 208-4370

Follow on Twitter @SupplyChainDave

During his career Dave Blanchard has led the editorial management of many of Endeavor Business Media's best-known brands, including IndustryWeek, EHS Today, Material Handling & Logistics, Logistics Today, Supply Chain Technology News, and Business Finance. He also serves as senior content director of the annual Safety Leadership Conference. With over 30 years of B2B media experience, Dave literally wrote the book on supply chain management, Supply Chain Management Best Practices (John Wiley & Sons, 2010), which has been translated into several languages and is currently in its second edition. He is a frequent speaker and moderator at major trade shows and conferences, and has won numerous awards for writing and editing. He is a voting member of the jury of the Logistics Hall of Fame, and is a graduate of Northern Illinois University.