Continuous Replenishment Lowers Logistics Cost

Continuous replenishment programs offer the potential for more efficient supply chain processes through a “pulled” system in which inventory information is shared between organizations and their suppliers. The supplier monitors inventory levels and automatically replaces materials as needed, thus allowing suppliers to more effectively plan for production and eliminating the need for purchase orders and other related paperwork.

APQC’s Open Standards Benchmarking in logistics indicates that 60 percent of responding organizations have implemented continuous replenishment programs for their customers to some degree. To gain insight into the effects of initiating a continuous replenishment program, APQC compared the logistics performance of organizations that have established these programs against that of organizations without these programs. The results indicate that continuous replenishment programs can lead to lower logistics costs and fewer employees in the logistics function but only slightly increase the quality of customer deliveries.

Logistics Cost and Resources

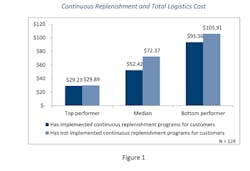

APQC’s data shows that organizations with continuous replenishment programs for customers spend less on logistics (Figure 1). At the median, organizations that have implemented these programs spend $19.95 less per $1,000 in revenue to manage logistics and warehousing functions than organizations without these programs. For an organization with $5 billion in revenue annually, this would mean a $99.8 million savings in logistics spending when using a continuous replenishment program.

The lower costs could be related to the fact that organizations with continuous replenishment programs need fewer full-time equivalent employees (FTEs) in the logistics function. At the median, these organizations need 96 employees per $1 billion in revenue for the logistics process, whereas organizations without continuous replenishment programs need 111 employees per $1 billion in revenue for the same function.

Both the number of logistics FTEs and overall logistics costs can be affected by the automated nature of continuous replenishment programs. Fewer employees are needed because the paperwork associated with traditional purchasing has been eliminated. Knowing the inventory levels of customers means that suppliers can better plan their own inventory and production to meet customer needs, which can reduce the amount of inventory held in supplier warehouses and the amount of warehouse staff. All of these factors can reduce the total amount organizations with continuous replenishment programs spend on logistics.

Delivery Quality

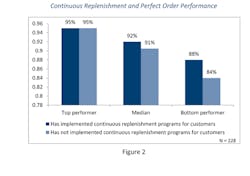

Organizations using continuous replenishment programs have only slightly higher perfect order performance than organizations without these programs (Figure 2). APQC defines perfect order performance as the percentage of deliveries made on time; arriving complete correct, and without damage; and arriving with an accurate invoice.

At the median, there is only a 1 percent difference in perfect order performance between organizations with continuous replenishment programs and organizations without these programs. These results indicate that the benefits resulting from continuous replenishment programs are primarily in the areas of efficiency and cost effectiveness rather than quality.

Establish Strategic Relationships

APQC’s data indicates that establishing continuous replenishment programs for customers can lead to lower overall logistics costs and fewer FTEs in the logistics function. If a supplier has access to the inventory information of its customers, this simplifies order processing by eliminating the need for purchase orders and other paperwork. It also provides suppliers with the ability to better plan production around demand, which can lead to a reduction in inventory as well as in employees needed for warehousing. However, continuous replenishment programs do not seem to have much effect on the amount of deliveries made on time, correct and without damage.

It is important to note that the benefit of establishing a continuous replenishment program goes beyond what can be immediately seen in logistics metrics. Suppliers can use these programs to further the development of strategic relationships with customers. Continuous replenishment programs provide an opportunity for suppliers and customers to work together to establish logistics processes that create value for both parties.

APQC is a member-based nonprofit and a proponent of benchmarking and best practice business research. Working with more than 500 organizations worldwide in all industries, APQC focuses on providing organizations with the information they need to work smarter, faster and with confidence.