The Smart Path to Accelerate Your Digital Transformation

Last year, the World Economic Forum named Fast Radius' new Chicago facility as one of nine top smart factories leading the pack in this fourth industrial revolution. That list has climbed to 16 this year and it's still the only North American company to gain the honor. The contract manufacturer, which focuses on additive manufacturing but also does CNC machining and injection molding, does it all when it comes to providing parts and services from design to delivery, and succeeds at two things extremely well: speed and quality.

Specifically, the WEF cited them for "Accelerating innovation and "meeting increasing demand for fast-turnaround and mass customization of products through distributed, industrial-grade 3D printing and proprietary operating system that drives real-time analytics and orchestrates, design, production and global fulfillment."

"These pioneers have created factories that have 20-50% higher performance and create a competitive edge,” says Enno de Boer, partner and global head of manufacturing at McKinsey & Co., which worked with the WEF on the selections, on the nine winners. “They are thinking ‘scale’, acting ‘agile’ and resetting the benchmark.”

The honor, and the company's very existence, comes a result of time-tested best practices and latest tech converging in the right place at the right time.

"This is a time of unprecedented innovation," says co-founder and CEO Lou Rassey, who began steering the company in 2017 and put the pedal to the metal in terms of accelerating that innovation. "And it's not just one tech. Additive is what we're excited about at Fast Radius, but there's a whole suite of other technology advancing, from robotics to digital simulation."

Even a few years ago, only the largest, capital-rich companies could explore them all, but that has also changed, according to Rassey.

"The beauty of them is that they are accessible," he says. "Any machine shop or manufacturer today can embrace applications such as printing tools and fixture and jigs."

And even if they don’t quite have a use today for a 3D printer, that could easily change.

"Every manufacturer might need to reflect on how these new tools might displace their method of fabrication and see if they need to make some new investments in some of these tools," he says.

Of course, the trick is to becoming a truly smart factory is to first purge ignorance, which due to hype and inexperience, anchors any emerging technology.

"There is a misperception in the industry that I can buy a 3D printing machine, plug it into the wall and get a good part out just like I could with a 2D paper printer," Rassey says. "For the industrial parts we're talking about, they're much more sophisticated. There is a workflow before the machine and after the machine with hundreds of variables that need to be dialed in and controlled to make sure you're getting an industrial-grade part reliably and repeatably."

In this way, speed doesn't come quick. That's something Rassey has known nearly his whole life.

Need for Speed

Rassey first developed a penchant for speed and precision listening to his paternal grandfather Louis' tales from the Indianapolis 500. After World War II, Louis and his team built and raced a lustrous orange roadster, the Automobile Shipper Special, to zoom around the Brickyard. The younger Rassey was too young to ever see the car compete, but vividly remembers—and lives by— the lessons instilled by grandfather who also manufacturer car parts a Detroit machine shop: Even the smallest change in quality can greatly increase performance.

It's not exactly the "With great power comes great responsibility" maxim Peter Parker got from his Uncle Ben, but it helped shaped who Rassey is, and by extension Fast Radius, which according to WEF rationale, is the "smartest" smart factory in America.

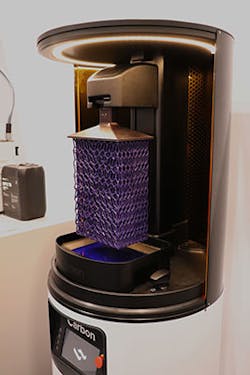

Being the smartest isn't necessarily dependent on having leading tech, although with the most industrial-grade machines from Carbon in the Americas and several HP MultiJet Fusion printers as well, it does. It's about how small tweaks like a lighter material, more aerodynamic shape, or faster production time can have a huge impact when added together.

"For one aerospace customer that had a critical need for a spare part, we were able to receive an order and fabricate it using additive manufacturing, validate it and get it halfway around the world all within 48 hours, when conventionally it would have taken 48 days," Rassey says.

In another instance, Fast Radius additive service produces one-third of the bill of materials for one automation company's new product. And in yet another, Fast Radius created a virtual parts warehouse (parts exist only digitally until needed) comprising 3,000 items for a heavy equipment manufacturer, which really adds up over time.

"The rule of thumb is the cost of storing a part is 25% of the total cost of part," Rassey explains. Therefore, a product manufacturer that needs to store parts for decade or more spends more on storage than production. And instead of making 20 of something, a just make one.

"These are real meaningful number when you look at the cost of the supply chain," he says.

A novel approach Fast Radius has taken even prior to Rassey's tenure, when the company was called CloudDDM, was constructing the production facility on-site at UPS' Worldport facility in Louisville. Parts could get printed, boxed and in the air almost instantaneously, akin to opening a wormhole in the supply chain.

Building Up

Because manufacturing excellence isn’t inherited by DNA, but earned through years of experience, Rassey's journey began small: sweeping up in his grandpa's machine shop, then slowly figuring out CNC programming and later became the shop's quality control guy.

The future engineer stayed in the Midwest to hone his mechanical mind at the University of Notre dame for undergrad and graduate studies at the University of Michigan to accrue management skills. Then in the late '90s he flew off to southern Brazil to help design a new factory for Chrysler.

Rassey then returned to the States for an MBA at the Massachusetts Institute of Technology before becoming a guiding voice for manufacturing executives as a partner at McKinsey. He led research in nearly every major advanced manufacturing effort, from robotics to the IIoT to 3D printing.

"I helped them have an outward focus on understanding what was around them and recognizing disruption can come their way," Rassey explains. "It was important for leadership to recognize the world was changing and figure out how to take action, run experiments and how to embrace the changes happening around them."

One thing Rassey noticed then, and still considers true now is that "executives know change is coming, but have a hard time figuring out how to take action on it."

The first step to solving this complex question came when Rassey left McKinsey to foster the creation of the Digital Manufacturing and Design Innovation Institute (DMDII), a 100,000-square-foot innovation center largely funded by the government focused on improving every facet of additive manufacturing, among them the economics and materials.

And appropriately things have come full circle for the Fast Radius chief, as the economics have improved to the point where even machine shops, like the one he used to sweep up, can now use the most advanced tech to drive efficiencies and shave lead times, as his grandfather did with powertrains 70 years ago.

The difference is that Fast Radius, as part of the WEF lighthouse network and not the competitive racing circuit, has agreed to share the secrets to how it accelerates innovation. It still all comes down to what small changes can be done in the design room, factory floor and supply chain to affect global change.

“We feed, power, connect and advance the world with the things we make," Rassey says. "We now have new and powerful tools at our disposal to make new things possible.

Lou Rassey will present the keynote "Digital Manufacturing Lessons Digital Lessons from North America's "Smartest" Factory" at the Manufacturing & Technology Conference on April 2. Register here.

About the Author

John Hitch

Senior Editor

John Hitch writes about the latest manufacturing trends and emerging technologies, including but not limited to: Robotics, the Industrial Internet of Things, 3D Printing, and Artificial Intelligence. He is a veteran of the United States Navy and former magazine freelancer based in Cleveland, Ohio.

Questions or comments may be directed to: [email protected]