Robot Eyes, the Ghost of Lordstown Motors and Watching Metal Melt: So That Happened

Editor’s note: Welcome to So That Happened, our editors’ takes on things going on in the manufacturing world that deserve some extra attention. This will appear regularly in the Member’s Only section of the site.

New Legal Hope for Nu Ride

The ghost of Lordstown Motors Corp. lives on for now.

The leaders of Nu Ride Inc., the successor to the electric-vehicle venture that filed for bankruptcy in mid-2023, said last week that a Delaware judge had ruled that a hatful of their claims of fraud and otherwise poor behavior against contract manufacturer Foxconn can proceed.

Nu Ride emerged from Lordstown’s Chapter 11 case in March of last year and has since been functioning as a vehicle for prosecuting and defending various legal matters. Most prominently, it has been carrying its predecessor’s case against Foxconn, which Lordstown brass said acted in bad faith when it signed an investment deal and then backed out as Lordstown’s situation deteriorated. The recent Delaware federal court ruling affirmed a bankruptcy court opinion that nine of Nu Ride’s 11 claims against Foxconn are not subject to mandatory arbitration and can move forward; the two others will—pending a Foxconn appeal—go before an arbitrator.

So it looks like there’s a long way still to go on this journey. Because of that, it’s worth noting that Nu Ride leaders have been pointing out for a while that the clock is ticking as it relates to their unrestricted cash holdings, which stood at nearly $27 million as of June 30: “No assurances can be provided as to the company having sufficient resources to pursue the Foxconn Litigation, the outcome or recoveries, if any.”

— Geert De Lombaerde

Give Your Robots Eyes

ABB Robotics recently announced an investment in LandingAI, a low-code visual AI platform, to mesh robotics and vision system technologies. As a former writer on Vision Systems Design this naturally caught my interest. I also pay attention to cases like these because they provide examples of how AI is actually useful in manufacturing.

One of the challenges with deploying robotics for delicate operations is figuring out pathing, literally how the robot arm will move, and making sure the robot manipulates the correct objects at the correct orientations. In the past one needed a programmer for this. Now it’s possible to equip robots with cameras that run vision software to recognize objects and guide movement of robot arms without guidance from humans.

In the case of this ABB investment, we’re talking about the ability to train robotic applications much more quickly than before by leveraging vision. ABB touts an 80% reduction in training time. Your mileage may vary. I know from experience that the vision technology is sound, however, and don’t consider this claim outlandish. Pairing robots with vision also makes it pretty simple to repurpose the robots into new operations.

So, while I rarely proselytize any specific technology, and this also isn’t meant as an endorsement for any particular company, inasmuch as my job is to help our readers improve their manufacturing operations, I do hope you pay attention to the intersection of robotics and vision technology and consider what you do with this pairing. There are real advantages to enjoy, within even SMB’s price ranges.

— Dennis Scimeca

What Do You Think About the USMCA? The Government Wants to Know

While many organizations and executives are still trying to wrap their heads around a complicated and ever-evolving U.S. tariff regime, some aspects have become clearer. Take the USMCA, for instance. Earlier this year, when the Trump administration announced and then retracted 25% tariffs on leading U.S. trading partners Canada and Mexico, questions emerged about this North American trade agreement and its role in preventing unilateral trade actions by partners to the pact. Why did USMCA rules seem to be absent from tariff decision-making?

Over time, clarity emerged. Goods qualifying under USMCA face no tariffs when imported in the U.S., says U.S. Customs and Border Protection. Of course, that doesn’t mean all disputes regarding the free trade agreement have gone away. The USMCA and its predecessor, NAFTA, have always had their detractors and supporters.

I bring this topic up because next year is a big one for the USMCA. The U.S., Canada and Mexico will hold a joint review of the North American trade agreement on July 1, 2026. In advance of that, Congress is seeking public comment on a host of elements related to the treaty. Individuals and organizations have until Nov. 3, 2025, to provide feedback, according to the Office of the U.S. Trade Representative and the Federal Register notice. A public hearing is slated to follow on Nov. 17.

Details about how to participate are included in the Federal Register (pdf) notice. If you want your voice heard, now is the time.

—Jill Jusko

The Scope (3) of the Supply Chain Emissions Problem

For the average company, Scope 3 supply chain emissions are 21x higher than Scopes 1 and 2 combined, according to the EcoVadis and Boston Consulting Group (BCG) 2025 Carbon Action Report: Scope 3: From Unmanaged Risk to Untapped Opportunity. Despite this figure, only 24% of companies report on Scope 3 emissions, just 8% have set an emissions target and only 4% have a science-based target.

The report found corporates could face over $500 billion in annual liabilities globally for Scope 3 emissions by 2030. However, BCG found that firms can reduce supplier emissions by on a cost-neutral basis by 50% (at or below $76 per metric ton CO₂e), and one-third of emissions can be reduced at less than $12 per metric ton, which unlocks up to a 6x return on investment through loss aversion.

The report has compiled five significant actions companies can take to support supply chain decarbonization:

- Engage and partner with suppliers

- Measure emissions

- Establish a climate-aligned management team

- Define a climate transition plan

- Allocate a dedicated emissions reduction budget

“By addressing Scope 3 emissions, companies can protect profitability while building a more resilient supply chain. The time to act is now, and the most effective place to start is with suppliers, where the majority of emissions lie,” said Pierre-François Thaler, co-founder and co-CEO of EcoVadis.

The report is based on EcoVadis data of more than 133,000 carbon ratings across 83,000 firms worldwide and BCG’s statistical analysis.

—Anna Smith

Watching Metal Layers Dry

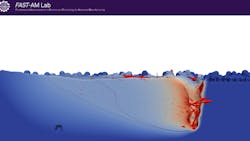

When metal melts, it often changes. Atoms line up in a crystalline structure as liquid metal cools, and dozens of variables can impact the shapes and mechanical properties of those structures. The difference between a hard metal, a brittle one, a slippery surface or an easily bendable one can be set during that phase shift from liquid to solid.

With metal additive manufacturing, many machines melt microscopic layers of metal on top of each other to create complex shapes that can’t be achieved with machining or other manufacturing techniques. That raises a big question: What exactly does that look like?

Researchers at Argonne National Laboratory in the Chicagoland suburbs have developed a system for watching, monitoring and measuring material properties of 3D-printed metals in hopes of understanding how materials behave and how they can tweak production and improve processes.

“Metals are made of atoms arranged in ordered crystal structures,” said Tao Sun, the project’s lead investigator and a professor at Northwestern University who also holds a joint appointment at Argonne. “But under rapid heating and cooling, some atoms fall out of alignment. These defects — called dislocations — can strengthen or weaken the final part.”

If you’ve ever been to Argonne (public tours require a bit of effort but are well worth the time), you’ll know that the massive facility is all about imaging – bombarding different materials and products with various energy types to visualize complex internal structures.

“Our analysis shows how powerful the [Argonne Advanced Photon Source] is for studying defects that were previously only seen through after-the-fact analysis,” said Andrew Chuang, a physicist at APS. “This is the first time this real-time technique has been applied to this laser-based method to study the dislocation evolution in a metal wire.”

Data revealed that dislocations form early, just as the metal changes from liquid to solid. It was previously thought that they form later as stresses build up during cooling and solidification. A key factor was a specific reaction in which two solid phases form at the same time from the liquid, creating a high density of dislocations.

“This type of 3D printing could create customized metal parts that are reliable and extra-strong and would survive extreme conditions,” said Lin Gao, a postdoctoral researcher in in the Nuclear Science and Engineering division at Argonne. “It may be key to building advanced metal components for next-generation nuclear reactors now being designed at Argonne and other labs.”

The National Science Foundation provided partial funding for this project. The findings were first published in Nature Communications.

The research was carried out by scientists from Northwestern University, Argonne, Oak Ridge and the University of Virginia. In addition to Sun, Gao and Chuang, authors include Yan Chen, Xuan Zhang and Sean Agnew.

—Robert Schoenberger

About the Author

Dennis Scimeca

Dennis Scimeca is a veteran technology journalist with particular experience in vision system technology, machine learning/artificial intelligence, and augmented/mixed/virtual reality (XR), with bylines in consumer, developer, and B2B outlets.

At IndustryWeek, he covers the competitive advantages gained by manufacturers that deploy proven technologies. If you would like to share your story with IndustryWeek, please contact Dennis at [email protected].

Anna Smith

News Editor

News Editor

LinkedIn: https://www.linkedin.com/in/anna-m-smith/

Bio: Anna Smith joined IndustryWeek in 2021. She handles IW’s daily newsletters and breaking news of interest to the manufacturing industry. Anna was previously an editorial assistant at New Equipment Digest, Material Handling & Logistics and other publications.

Robert Schoenberger

Editor-in-Chief

LinkedIn: linkedin.com/in/robert-schoenberger-4326b810

Bio: Robert Schoenberger has been writing about manufacturing technology in one form or another since the late 1990s. He began his career in newspapers in South Texas and has worked for The Clarion-Ledger in Jackson, Mississippi; The Courier-Journal in Louisville, Kentucky; and The Plain Dealer in Cleveland where he spent more than six years as the automotive reporter. In 2014, he launched Today's Motor Vehicles (now EV Manufacturing & Design), a magazine focusing on design and manufacturing topics within the automotive and commercial truck worlds. He joined IndustryWeek in late 2021.

Jill Jusko

Bio: Jill Jusko is executive editor for IndustryWeek. She has been writing about manufacturing operations leadership for more than 20 years. Her coverage spotlights companies that are in pursuit of world-class results in quality, productivity, cost and other benchmarks by implementing the latest continuous improvement and lean/Six-Sigma strategies. Jill also coordinates IndustryWeek’s Best Plants Awards Program, which annually salutes the leading manufacturing facilities in North America.

Have a story idea? Send it to [email protected].

Geert De Lombaerde

Senior Editor

A native of Belgium, Geert De Lombaerde has been in business journalism since the mid-1990s and writes about public companies, markets and economic trends for Endeavor Business Media publications, focusing on IndustryWeek, FleetOwner, Oil & Gas Journal, T&D World and Healthcare Innovation. He also curates the twice-monthly Market Moves Strategy newsletter that showcases Endeavor stories on strategy, leadership and investment and contributes to other Market Moves newsletters.

With a degree in journalism from the University of Missouri, he began his reporting career at the Business Courier in Cincinnati in 1997, initially covering retail and the courts before shifting to banking, insurance and investing. He later was managing editor and editor of the Nashville Business Journal before being named editor of the Nashville Post in early 2008. He led a team that helped grow the Post's online traffic more than fivefold before joining Endeavor in September 2021.