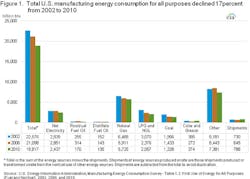

Total energy consumption in the manufacturing sector decreased by 17% from 2002 to 2010, according to data released today by the U.S. Energy Information Administration. Manufacturing gross output decreased by only 3% over the same period. Taken together, these data indicate a significant decline in the amount of energy used per unit of gross manufacturing output. The significant decline in energy intensity reflects both improvements in energy efficiency and changes in the manufacturing output mix. Consumption of every fuel used for manufacturing declined over this period.

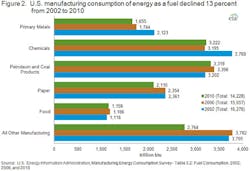

U.S. manufacturing used over 14 quadrillion Btu of energy as a fuel in 2010, a decrease of 13% from the 2002 level. Fuel consumption in the five most energy-intensive subsectors accounted for 81% of fuel use in manufacturing. Two energy-intensive subsectors petroleum and coal products, and food showed 3.5% increases in their fuel consumption from 2002 to 2010.

While overall manufacturing output declined by 3% between 2002 and 2010, some manufacturing industries grew over the period. The gross output for the petroleum and coal products subsector grew by about 3%, while the gross output for the food subsector increased by 5%. However, during this same period the number of employees in both subsectors fell, the petroleum and coal products subsector by 6,000 employees, and the food subsector by 115,000 employees. The reduction in employment, along with an increase in gross output, signals an increase in labor productivity in these two subsectors.

These data, among others, are drawn from the detailed results of EIA's 2010 Manufacturing Energy Consumption Survey (MECS).

About the Author

IW Staff

Find contact information for the IndustryWeek staff: Contact IndustryWeek