Determine if Smart Sensors are Needed in Your Industrial Machines

Sensors are essential in capturing basic diagnostics from industrial machines and equipment. As the people maintaining the machines are nearing retirement, a new, younger workforce is emerging that is comfortable with technology and the data that comes with it. As a result, manufacturers need to find ways to transfer that domain knowledge from the retiring generation into today’s smart machines to aid the upcoming generation of maintenance engineers. It will be key to manufacturer success to capture contextual data to provide more predictive diagnostics and leverage data across the manufacturing enterprise. A new wave of smart sensing technology is fulfilling this need – bringing deep insight into the health of industrial machines.

Sensors are Getting Smarter

Sensors enabled with IO-Link technology can communicate more data, allowing machines to operate more effectively. In fact, standard sensors are limited to indicating the presence and/or absence of an object, while smart sensors can provide up to 32 bytes of cyclical data including diagnostics not only for the sensor but about the application environment. Some examples are sensor status, dirty lens indication (in the case of photoelectric sensors), and sensor internal temperature (for proximity sensors). Plus, these smart sensors offer other advanced functions that make setup, maintenance and troubleshooting much more efficient, including the storage of multiple machine profiles to simplify parameter adjustments during line/shift changes as well as automatic device replacement, which feeds previous sensor configurations directly to new sensors as they are replaced.

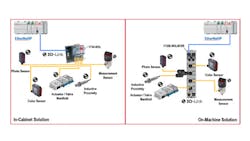

IO-Link is an open-standard protocol (IEC 61131-9) that provides a common experience for users regarding many sensor parameters and features. IO-Link masters are gateways that allow IO-Link devices to connect to other networks on the machine — such as EtherNet/IP™ —that share the information with the control system. This brings a wealth of detailed, machine-health diagnostics to operators and maintenance personnel.

While smart sensors offer key insights into a manufacturing operation, it’s not necessary for all sensors to be enabled with this technology. Sensors in non-critical applications or those that rarely have issues (e.g. “clean” applications where sensor lenses aren’t prone to getting dirty) may not need this technology. Sensors that often become dirty, become damaged during normal operations, experience extreme climate conditions and/or need their parameters changed on a somewhat regular basis, however, would be ideal candidates for “smart” sensing capabilities. To determine if switching to smart sensors is the right decision for you, consider these key questions:

- Does the sensor need frequent cleaning?

The environment where sensors operate can drastically affect the data they transmit. For instance, photoelectric sensor lenses that are often blocked by debris, need frequent cleaning or are easily damaged are prime candidates for a smart-sensor upgrade.

A smart sensor will transmit more detailed information about sensor issues including when they occurred and the source of the issue. This gives OEMs the ability to quickly respond or schedule routine maintenance, thus helping increase operational efficiency and decrease downtime.

- Does your operation require repeated line changes?

Operations that involve frequent line changes with different-size products may be simplified with the installation of smart sensors.

Rather than manually configuring the machine for each product change, smart sensors with IO-Link technology can store multiple profiles in the controller, which can push them down to the sensor when needed. This provides a few benefits: The user no longer needs to remember each sensor configuration. The same parameter values are sent to the sensor each time, eliminating potential variations made by the person who is teaching the replacement sensor. It also significantly decreases the sensor configuration time from several minutes down to milliseconds.

- How often is this sensor subject to damage?

Frequent damage to the face of the sensor can cause the device to lose its ability to detect the presence of objects around it. Often in inductive proximity sensor applications, the sensor and the target must be very close and through normal wear and tear of the machine, they can impact one another. In most cases, the damage is most likely limited to the sensor face and not necessarily the internal coil of the sensor. When this happens, standard sensors do not always convey when something is amiss. The LED could still indicate proper function (power is applied), regardless of whether an object is present. This offers no clear indication that there is an issue.

With the installation of smart sensors, diagnostic information is sent back to the controller, alerting OEMs that the sensor needs attention and potentially replacement. In addition to damage detection, advanced diagnostics could alert operators when there is a dirty lens (on photoelectric sensors), misalignment, low margin or overheating. The ability of smart sensors to timestamp a change in process state or event also helps track when the sensors went offline or when operating parameters have been changed.

- Is this sensor vulnerable to temperature changes?

Extreme temperatures can put enormous strain on many sensors. Devices that regularly experience extreme hot or cold environments are vulnerable to damage, limiting their ability to report diagnostics.

Installing IO-Link technology allows OEMs to monitor the temperature of the sensor, and predict if and when the device could be compromised. This reduces the chances of disruption in the manufacturing process and helps limit time spent on restoring operations.

Additional smart-sensor considerations

Smart sensors with IO-Link technology often have the same catalog number as the standard sensor. This permits machine builders the flexibility of specifying (and stocking) one catalog number whether they need a standard sensor or a smart sensor in their application. Only when an IO-Link master is used will the sensor behave in a “smart” manner. This allows the machine builder to only add cost to the machine when they use the IO-Link master. When using other communication methods, different sensor catalog numbers and communication media are often required to enable the smart devices. EtherNet/IP is still the leading network for industrial operations, according to a 2016 IHS analyst study. Some devices, like sensors, would not be an ideal candidate for this technology. That is where IO-Link is a key “linking technology” for The Connected Enterprise, enabling smart sensors to provide Ethernet-like connectivity and features without the added cost and complexity of pure Ethernet-enabled field devices.

Calculate the cost of sensor configurations for line changes and the downtime related to sensor malfunctions to determine if making the switch is right for you.