Our outlook for the year ahead anticipates a continuation of the many disruptions we are currently seeing at every stage of the supply chain. Suppliers themselves are struggling to maintain capacity. Even when suppliers are ready to ship, more disruptions create havoc in getting required inputs promptly to the manufacturer. These disruptions include container shortages, long-range logistics, shipping terminal and port congestion and backlog, labor shortages, remote working, adherence to quality requirements and standards, increasing fuel prices, and rapidly rising inflation. This list is by no means exhaustive but should certainly be sufficient to create a sense of urgency in developing and executing supply chain strategies to combat the risks of continuing supply constraints.

Given the myriad of supply chain challenges highlighted, it can be a daunting task to know where best to conserve and prioritize energies and resources to mitigate critical risk and provide the best ROI. It is crucial for smaller manufacturers because they do not have the luxury of sizable supply chain functions aligned with robust processes to continually drive improvements and mitigate risk.

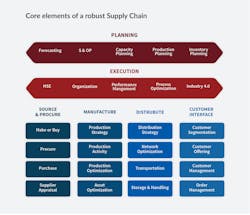

There is no one-size-fits-all strategy or approach. Each organization must conduct a thorough assessment of the core elements of its supply chain (see model on next page) to ascertain which parts need to be addressed as a priority to mitigate the most pressing risk.

Some of the common themes that we see include:

- Moving away from single sourcing (where possible) and creating a strategic sourcing mix of domestic as well as existing global suppliers

- Addressing extended lead times in Demand Planning and Forecasting

- Logistics and transportation strategies to address anticipated extended lead times

- Use of third-party providers to manage risk and utilize providers’ leverage in the market

- Implementing digitalization strategies

- Integrated and dynamic Management Operating System to provide better visibility of performance across the entire Supply Chain

- Improving data capture and integrity

- Inventory strategies

Again, this list is by no means exhaustive but demonstrates that manufacturers must take immediate actions to ensure that they not only survive but thrive in this rather challenging environment. Smaller manufacturers especially do not have the luxury of a “wait-and-see” attitude to see if these supply chain constraints continue to deliver the same impacts in this coming year.

We do not believe that things will get better in the short term but continue to work on the premise that most manufacturers have more control over their supply chains than many may assume. The key is to ensure that you continually and proactively look to optimize every element of your Supply Chain.

Sponsored By: