Supply Chain Metrics: Sharing of Real-Time Demand and Inventory Data Yields Mixed Results

Increased information visibility is a goal for many organizations. For the supply chain, many organizations look to the sharing of real-time, electronic demand and inventory levels for greater visibility, which can lead to better inventory levels and shorter order processing times.

APQC’s Open Standards Benchmarking in logistics reveals that a little over half of responding organizations (58%) have made real-time demand and inventory data available to the enterprise. Of these respondents, 31% have adopted the practice to some degree and 27% have adopted the practice extensively.

To determine the potential impact of sharing demand and inventory data, APQC compared the logistics performance of organizations that have and have not adopted this practice. The responses indicate a mix of positive and negative results associated with the practice that call into question how organizations use their access to real-time demand and inventory data.

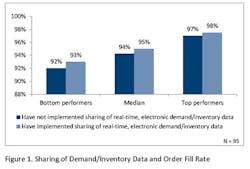

Order Fill Rate

APQC’s data shows that organizations sharing real-time demand and inventory data have slightly higher order fill rates than organizations that have not adopted this practice (Figure 1). There is only a 1% difference in order fill rate between the medians of the two groups.

These results are logical given the improved inventory tracking enabled through the sharing of real-time inventory and demand data. An organization can fill more orders completely if the product needed for the order is in stock. However, the small difference between groups that use real-time data and those that do not may indicate that organizations that have not adopted this practice may take other measures to ensure inventory is closely tracked. Bottom performing organizations that have not implemented the practice attain an order fill rate of 92%; this number could be improved upon, but it is not significantly low.

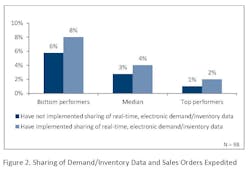

Sales Orders Expedited

Surprisingly, APQC’s data indicates that organizations sharing real-time, electronic demand and inventory data expedite more sales orders than organizations that have not adopted this practice (Figure 2). The difference between the groups is not large, but bottom performing organizations that share real-time data expedite 2% more of their orders than bottom performing organizations that do not share real-time data. This difference can translate into additional costs for expedited shipping as well as additional time needed to process rushed orders.

APQC’s data hints at a disconnect between the adoption of information visibility practices and the actual use of the information. The adoption of real-time information sharing is intended to give organizations a better idea of what products customers will be ordering so that they can meet customer needs. However, the information is only as good as the actions it spurs organizations to take. If an organization does not use the information available or if it uses the information but takes no steps to improve poor logistics processes, the organization will see logistics performance stagnate or suffer.

Information as a Starting Point

Having access to real-time data regarding demand and inventory levels can give an organization the ability to better meet customer needs. However, simply having the information available is not enough. In order for information visibility to have value, organizations must make sure their logistics processes are efficient and the information is strategically leveraged. APQC’s data indicates that many organizations have taken the step to gain access to real-time data, but these organizations have not fully realized the benefits possible from this practice.

Organizations seeking to gain access to real-time, electronic demand and inventory data should not let the logistics performance of other organizations deter them. Instead, organizations should ensure that they have efficient logistics processes and strategies for how information is used. Having these items in place will allow organizations to experience the full benefits of supply chain visibility.

APQC is a member-based nonprofit and a proponent of benchmarking and best practice business research. Working with more than 500 organizations worldwide in all industries, APQC focuses on providing organizations with the information they need to work smarter, faster and with confidence.

Related Articles:

Supply Chain Metrics: Improve Supply Chain Planning with S&OP

Inventory Accuracy Improves Performance on Logistics Metrics