Many companies are considering expanding U.S. sourcing or reshoring production back to the U.S. in an effort to be located closer to customers. Some of the benefits of sourcing locally include increased flexibility to adapt to variable demand, lead time, time to market, eliminating higher shipping expenses and minimizing supply chain disruptions.

As companies consider new locations and production strategies they must first decide what areas they want to invest in and where they want to rely on suppliers. In a recent article in MIT Sloan Management Review by Willy C. Shih (“What it Takes to Reshore Manufacturing Successfully”) a manager from Appliance Park was quoted as saying, “Pick where you want to invest in core competencies, and acknowledge where you want to have strategic suppliers—where you aren’t going to make the deep investment yourselves.”

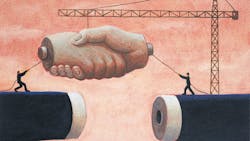

Next, buyers need to find strategic U.S. suppliers with the right capabilities, capacity and quality performance needed for the job. However, due to years of offshoring, the U.S. supplier network has incurred some structural damage and new U.S. supply chains must be rebuilt and managed.

As manufacturers are rethinking production locations and supply chain options, rebuilding and mapping the American supplier network is becoming increasingly important. To help facilitate successful U.S. sourcing we must:

- Bridge the gap between buyers and U.S. suppliers.

- Forge strategic relationships.

- Collaborate to solve design and production issues.

Bridging the Gap

Creating high performance, collaborative alliances between buyers and U.S. suppliers will ensure rebuilding a strong and sustainable American supply chain. However, as cited by The Milstein Commission on New Manufacturing, Co-Chaired by Haley Barbour, Former Governor, Mississippi and Evan Bayh, Former Governor and U.S. Senator, Indiana, many small and medium companies do not possess the know-how to locate the suppliers needed to move beyond the design stage. They simply do not have the resources to fully leverage the U.S. supply chain. In turn, potential U.S. suppliers lose out on opportunities.

Streamlining Supplier Discovery

Partnering with an E-sourcing company can streamline supplier discovery.

BUYERS

- An e-sourcing platform can save buyers time so they can concentrate on their core income-generating business responsibilities.

- E-sourcing can streamline the sourcing process and locate the U.S.-based suppliers with the expertise and the machine assets needed for the job.

- Buyers can quickly receive quotes and easily compare and identify the best match.

- E-sourcing can help managers make better decisions in terms of costs and quality.

SUPPLIERS

- Suppliers can get in front of live RFQ opportunities at the time when buyers need their custom services.

- An e-sourcing platform is a powerful business development tool that can promote the suppliers’ capabilities and services and boost machine uptime by getting in front of a greater number of opportunities.

- Suppliers can review engineering documentation and CAD files and respond to RFQs effectively and in a timely manner.

E-sourcing technology can be a fundamental component in connecting buyers with U.S. suppliers, as well as an efficient way to facilitate a level of collaboration to build and sustain solid relationships.

Forging Strategic Partnerships

One new model for building strategic partnerships between buyers and suppliers incorporates a cooperative relationship of “co-innovation” that includes information sharing and collaboration to solve design and production issues – buyers and suppliers should be collaborating and innovating together.

Adopt a strategic view of buyer/supplier relationships

BUYERS

- Collaborate with your supplier network to maintain optimum productivity and profitability for your manufacturing operation.

- Be sure to communicate clear and specific details about the job to receive an accurate quote.

- Effective communication with suppliers will optimize efficiency, accuracy and profitability.

- Remain positive to an open exchange of communication, information and suggestions to solve problems and create better processes.

SUPPLIERS

- Communicate with customers and potential customers to forge strong relationships and build trust.

- Provide quality performance and good customer service to create repeat customers who will in turn become advocates for your company and services.

- Stay engaged with customers to keep in front of potential problems.

The success of revitalizing the U.S. manufacturing base lies in delivering efficient communication and coordination to the buyer/suppler relationship.

The Technology Connection

As global competitors invest in technology for their own domestic supply chains, companies in the U.S. may like to consider implementing new technology, processes and automation as well as take advantage of the close proximity of product design and manufacturing to promote innovation. Lean manufacturing, new technology and collaboration between buyers and suppliers can eliminate unnecessary parts and processes resulting in significant cost savings. Considering these methods early on in the product development and reevaluating design from a manufacturing standpoint many times leads to better design decisions that reduce costs.

Examine and consider new technology and processes

BUYERS and SUPPLIERS

- When manufacturing is moved next to design and design engineers are working closely with manufacturers, they can improve the design, eliminate waste, improve quality, increase productivity and make the product more easily and efficiently.

- Lean manufacturing practices, automation and innovation are critical elements in rapid customization, reducing costs, shorter lead times and more rapid product cycles.

- Embracing new technology, training and methods can build competitiveness, expand capabilities, increase efficiency and possibly add to your bottom line.

Considering these concepts may lead to opportunities that can be crucial to the growth, success and sustainability of your business. Lean processes and automation are tools that can boost productivity, and when productivity is increased, it reduces the total cost vs. offshore and drives U.S. competitiveness. Streamlined supplier discovery, communication and collaboration and reevaluation of product design will help create a focused strategy for growing domestic manufacturing and facilitating successful U.S. sourcing to rebuild a sustainable American supplier network.

Robert Moakler is COO of Fabricating.com, an online marketplace exclusively developed for the American manufacturing industry. The company connects U.S. buyers with U.S. suppliers through an online platform for sourcing custom metal and plastic parts in over 250 manufacturing disciplines.