Manufacturing's Talent Offensive: Better-Defined Roles, Factory as Classroom, Building Community

Key Highlights

- Defining roles based on performance, learning pathways, and cultural expectations can improve alignment and workforce readiness.

- Instead of waiting for schools or policymakers to address the talent gap, Humtown Products took the initiative to create a living workforce laboratory for students.

- Staub Manufacturing Solutions' investment in mentoring, cross-training and clear career paths has paid off in a turnover rate of less than 5%.

At this year’s Ohio Manufacturing Association Workforce Summit, one message came through clearly: It’s time for U.S. manufacturing to go on offense.

For decades, workforce development has been played defensively: scrambling to fill positions, reacting to retirements and patching talent gaps after the fact. The stakes are now much higher. According to the Reshoring Initiative, reshoring and foreign direct investment accounted for nearly 245,000 U.S. manufacturing job announcements last year, and early reports suggest 2025 will finish at a similar pace.

The opportunity is real, but so is the pressure. As companies bring production closer to home and new technologies reshape operations, manufacturers can no longer afford to wait for the next labor shortage to dictate their strategy. They must design for it. Many already are defining roles more precisely, investing in people and building community-rooted cultures to turn workforce challenges into competitive advantage.

Takeaway #1 Define Roles with Precision

In workforce development, clarity is power. Across the manufacturing ecosystem, however, role definitions often break down in translation. Education and training providers may certify learners as “job-ready,” while employers still struggle to find skilled candidates who fit specific production needs.

The issue isn’t that manufacturers lack job descriptions: It is that the broader ecosystem lacks a shared language for skills. When each actor defines “technician” or “technologist” or “engineer” differently, alignment suffers. Schools teach to one version of the role; employers hire to another, and workers are left trying to connect the dots.

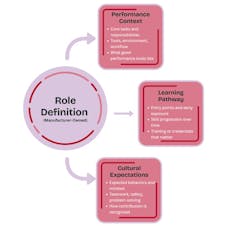

During a consulting project this summer, I saw how alignment improves when companies lead with clarity. Instead of starting with titles, we mapped each role by its performance context (where and how the work happens), learning pathway (how the role is prepared) and cultural expectations (how success is recognized).

The exercise revealed that some capabilities manufacturers struggle to find are already present in adjacent technical roles, hidden in plain sight because of mismatched language and classification.

When manufacturers take the lead in defining roles collaboratively with those within their ecosystems (educators, workforce boards and community partners), they shift workforce development from crisis response to strategic design. The payoff is faster onboarding, clearer career ladders and partnerships that build the right skills, not just more programs. Ohio’s competency model offers a practical template for translating manufacturer-defined roles into shared skills language that education and workforce partners can use.

By following this sequence, manufacturers can ensure consistent role and skill language at every point where a learner or worker connects with their system: When everyone along that continuum—from educators to employers—uses shared role definitions, training investments align more closely with operational needs, and learners can see a clear path from classroom to career.

Takeaway #2 Put Real Skin in the Game: Humtown Products

In Columbiana, Ohio, Humtown Products is showing what it looks like when a manufacturer takes the initiative. Instead of waiting for schools or policymakers to address the talent gap, President Mark Lamoncha turned his factory into a classroom. Middle and high school students from across Northeast Ohio and Western Pennsylvania don’t just tour the facility—they lead tours and run demonstrations for their peers and learn the rhythm of production firsthand. What began as community outreach has become a living workforce laboratory.

The impact speaks volumes. More than 1,000 students have experienced manufacturing not as a distant concept but as a tangible, creative career path. Teachers and local workforce boards now use Humtown’s model to shape lesson plans and career awareness events. And it’s paying off: Several students who were first introduced to Humtown through tours later participated as peer tour guides and supervised hands-on learning activities, already fluent in the shop’s culture and tools.

As Lamoncha puts it, “When we see young adults as emerging industrial athletes, blending classroom learning and real-world experience, they begin to discover what truly sparks their interest—and just as importantly, what doesn’t. Interest becomes the gateway to purpose, which fuels passion and engagement. This is how a young person moves from choosing a job they ‘have to do’ to finding meaningful work they ‘want to do’—work they love and can engage with for a lifetime”.

Humtown’s model proves that meaningful workforce development doesn’t have to start with million-dollar grants or statewide initiatives. It can begin right on the shop floor, with a single company inviting the next generation to learn by doing. Small manufacturers can shape the future by turning operations into learning spaces—and in doing so, transform community curiosity into a sustainable talent pipeline.

Takeaway #3 Build Culture as a Workforce Strategy: Staub Manufacturing Solutions

At Staub Manufacturing Solutions in Dayton, Ohio, workforce strategy does not start with recruitment, but with respect. Co-owner Steve Staub told the Dayton Business Journal that solving workforce shortages begins with how companies treat people—by building workplaces where employees feel valued, connected and proud to represent manufacturing.

That philosophy runs through everything Staub does, from open-house tours for students to everyday shop-floor practices. The company invests in mentoring, cross-training and clear career paths that help employees see long-term futures in the industry. It also partners with schools and community organizations to show young people that manufacturing offers meaningful, stable careers. Inside the plant, leadership transparency and consistent recognition sustain engagement long after onboarding.

The results speak clearly: Staub reports an annual turnover rate of less than 5%, compared with an industry average of nearly 40% in metal fabrication. That difference reflects deliberate choices, not luck. In Staub’s words: “Having a culture where folks are treated with respect and everybody gets along is a really big thing. People don’t want to leave a company if they’re happy.”

For manufacturers looking to revisit their own workplace culture, Staub’s example offers a practical starting point:

Lead with respect. Make a respectful environment non-negotiable; it’s the foundation for retention.

Hire for attitude; train for skill. About 65% of Staub’s workforce joined with little prior experience. They were trained internally for long-term growth.

Invest in people benefits. Staub covers 80% of employees’ health insurance costs—well above industry norms—as part of a long-term retention and workforce-stability strategy, not simply to meet compliance requirements.

Expose students early. Through STEM enrinchment and robotics competition programs like Xtreme STEM and Xtreme BOTS, Staub helps local students build, design and compete, showing them that manufacturing is creative, not monotonous.

Focus on teamwork and soft skills. As Staub notes, “Collaboration is the most important skill in manufacturing.” Building those habits internally pays dividends externally.

By viewing culture as a business strategy, not an afterthought, Staub has built a workforce that’s loyal, skilled and growing. His story is a reminder that retention isn’t mysterious. It’s the outcome of everyday choices that show people they belong they matter, and they can build a career that lasts.

Playing offense in workforce development means leading with clarity, commitment and community. Clarity in defining the roles and skills that truly drive production. Commitment in taking ownership of the talent challenge. And community in building workplaces where people belong, learn and grow.

U.S. manufacturing’s future will be written not by those who wait for perfect policy or funding, but by those who design systems that work right where they are. The examples of Humtown and Staub show that regardless of company size, manufacturers can lead a movement when they treat workforce strategy as part of their core business, not a side project. The next generation of manufacturing leaders won’t wait for talent; they’ll design for it.

About the Author

Winifred Opoku

Doctoral Candidate, Ohio State University College of Engineering Education

Winifred Opoku is currently pursuing her doctorate in the Department of Engineering Education within the College of Engineering, at The Ohio State University. She worked in various roles in the energy industry including, mechanical design engineer, HVAC Tech Assistant, and workforce development specialist, prior to pursuing her PhD. She has a wealth of experience in teaching and technical training across various settings: first-year engineering classrooms, academic mentorship programs, K-12 STEM outreach, HVAC design, and in corporate spaces.

As a rising engineering education scholar and workforce development practitioner, she aims to use her knowledge to provide tools to design more effective learning experiences for different kinds of learners in the engineering and technical workforce.