3D Printing Lessons Learned from COVID-19 (And How They Will Change Manufacturing’s Future)

For manufacturers and consumers alike, COVID-19 has been both a humbling reminder of infrastructure fragility and an accelerant for change. The global supply chain was upended in ways never seen before. We learned quickly what it meant to lack access to everyday items. And hospitals grappled with a lack of critical life-or-death resources.

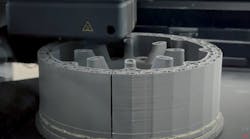

As a result of these challenges, this crisis brought 3D printing into countless people’s lives for the very first time. For many, their introduction to 3D printing technology has been personal protective equipment (PPE) or testing equipment—like a face shield, mask, or nasal swab—helping them stay safe. That’s a profound human experience.

Well beyond this pandemic, the recent lessons we have learned from 3D printing will propagate throughout future-minded industries and into consumers’ lives in four critical ways. Supply chains will transform; creativity and design will accelerate; entire ecosystems will realign; and values will progress.

1. Supply Chains Must be Engineered to Adapt

More than 51,000 companies had at least one key supplier in the Chinese provinces most impacted by the coronavirus outbreak, according to a study conducted by Dun & Bradstreet in February. But supply chain disruption reaches much further. In Europe, reports indicated that trucks were backed up 40 miles at one point at closed borders—a snapshot of the challenges many countries have faced. In fact, a March study of supply chain exposure throughout the Eurozone revealed that basic metals, fabricated metals and rubber and plastics were impacted 2% to 4% due to China’s and Italy’s massive COVID-19 exposure. While those fluctuations seem small, there is a ripple effect. The realities impacting each region and the larger global supply chain mean new solutions have to be engineered with a very clear goal in mind: Supply chains cannot just center on efficiency; they must also focus on risk mitigation. Whether it is a healthcare crisis, or economic or geopolitical volatility, companies and consumers have learned that digital manufacturing capabilities can be a valuable safeguard against external risk factors, reducing or altogether eliminating the downtime of trying to find more local or accessible suppliers. This was the case for Washington-based Superfeet, a manufacturer of insoles. Rather than rely on distant supplies procurement, the company used 3D printing to cut out the middleman, which meant production of its usual insoles could continue along with face shields during COVID-19.

2. Innovation That Reimagines Can Also Reconfigure in a Crisis

Access and readiness can’t be understated in the future of manufacturing. Companies that were able to leverage digital manufacturing to shift their operations in just days want to harness that speed and agility again—either with new solutions or by reconfiguring existing ones. What’s also intensifying is the drive for innovative companies to unseat incumbent legacy brands through technology. What COVID-19 taught us was that the same mindset that allows companies to disrupt industries in the first place also moves them to reinvent during a crisis. For instance, SmileDirectClub disrupted the $12 billion orthodontics industry thanks to the individual patient customization and scalability 3D printing enabled for dental aligners. As the pandemic worsened, the company pivoted its production to PPE-and on April 15 announced that it had delivered 35,000 face shields to essential workers. After a year of rapid expansion and massive technology investments, SmileDirect’s agility allowed the company to continue using its fleet of 60 printers and retain its manufacturing employees without the supply chain disruption worries of traditional manufacturing. It also enabled them to produce PPE for their own global workforce as well as its valuable partners in the dental industry—partners whose profession comes with an especially high level of risk.

3. Value-Driven Collaboration Is No Longer Optional

COVID-19 has also opened up new avenues for collaboration. As we move forward, companies need to rethink how they compete in the new normal. In 2015, BCG studied what percentage of companies, identified as “strong innovators,” embraced ideas that emerged from partnerships with other companies. Then, 65% did. In 2018, BCG found that number had grown—83% of strong innovators were collaborating outside the company, often with multiple industries. Around the world, companies that used 3D printing during this crisis have often echoed a similar sentiment about business collaboration across sectors, across borders and even competitors coming together—to share ideas, build on each other’s designs, and create new value for customers—and for themselves. These months have been an indisputable proving ground for what’s to come in manufacturing, and it is rooted in an ecosystem mentality. Now, more than ever, valuable collaboration is imperative for success.

4. Sustainability Has to Be Built In, Not Tacked on

In the midst of COVID-19, we were given a stark reminder of the pressure our environment is under. More than half of consumers say their experiences during the pandemic will make them more likely to purchase environmentally friendly products, and 78% t say companies could do more to help them make decisions that improve environmental outcomes. Those glimpses of cleaner water and clearer air must remain at the forefront of innovation and be a primary consideration for manufacturers who are rebuilding their operations right now. Environmental benefits are inherent to 3D printing—from lower distribution emissions, to more eco-friendly materials, to the fact that less material is required for production, We’ve known for some time that more sustainable production is table stakes for companies that want to compete in the future. What cannot be overlooked, however, is the role businesses play in shaping the community aspect of sustainability. After all, caring for the planet is also about caring for people. The tragedy of COVID-19 proved to be a master class in manufacturing that benefits mankind. Nearly every company or university with 3D printing capabilities seemed to answer incredible necessity with humanity, not profitability, in mind, and that instinct cannot dissipate even as this virus does.

Innovation emerges from times of great intensity. 3D printing helped the heroes of this pandemic and earned a new place in the minds of consumers and creators as a result.

Ramon Pastor is interim president of 3D Printing & Digital Manufacturing, HP Inc.