WICHITA, Kan. — For now, most folks know about Wichita State University because of its basketball team and, maybe, because of its pizza history. Soon, though, the most public face of the fifth-largest institute of higher learning in Kansas could switch from its Shockers or the first Pizza Hut to innovative advanced manufacturing.

Wichita State officially opened the doors to its new 3DEXPERIENCE Center last Thursday — the product of a partnership between Dassault Systèmes and the school’s National Institute for Aviation Research (NIAR) that adds more than 120,000 square feet of lab and work space to a burgeoning Innovation Campus. Students can work on practical projects and enter the workforce as experts on the latest tech. Regular folks can walk right in and fiddle around in an expansive makerspace. And the school can pitch itself as far more than an NCAA Tournament regular.

If the Innovation Campus continues to develop as planned, it could provide another blueprint for how to blend higher education with major companies and, of course, practical skills designed for students to land that first (and second, and third) job.

“This center ticks a lot of boxes for people like me,” said Michel Tellier, VP of aerospace and defense for Dassault. “A center like this allows us to create an operational metaphor where that end-to-end capability is actually implemented and in operation. I can bring our customers here and they can understand what technology can do for them — and, more important, they can experiment.”

The center serves plenty of other purposes, too. It provides lab space for aerospace startups to innovate and perhaps develop prototypes. It helps develop a new crop of engineers, some of whom might land at Dassault (or at Airbus, which is a partner and also now has more than 300 employees at work on commercial aircraft products in offices in a neighboring building on campus). Perhaps most important for Wichita State, it provides a physical center for a planned Innovation Campus that will cover more than 120 acres and open the school to a wider audience.

“What we are hoping to be is a center of creativity throughout this entire region,” Wichita State president John Bardo said. “We’re trying to diversify so it’s not only engineering — we want to include business processes, accounting processes, computer science, criminology, we even a group of arts people who are talking about coming.

“It’s about, ‘How do you think differently?’”

So, how did Dassault and Wichita State think differently? A two-hour tour of the building shows off plenty of that thinking and highlights the different stages of the development program. Classrooms and labs are dedicated to ideation, mission planning, and concept of operation; detail definition; reverse engineering; virtual reality; additive manufacturing; and robotics. One windowless room houses what Tellier describes as “the largest high-definition CAVE (Automatic Virtual Environment) in the world.” Another is home to nine ABB industrial robots that comprise “probably the largest (multi-robotic advanced manufacturing space) running right now.”

“This is where engineers can understand the application of what they’re learning as they study, and where they can gain exposure to multiple aspects of the product development process,” Tellier said. “We have a responsibility to help create the next generation of engineers, and having them work on the state-of-the-art is definitely the right thing to do.

“We don’t want to restrict this just to aerospace. What we’re doing here will bring value to other companies that want to understand how products can be innovated, created, regulated, and we want to learn for aerospace from other industries. There’s no question there’s a bias for aerospace, but you need to have some cross-pollination for it to be really viable.”

As the Air Capital of the World for close to nine decades, Wichita has plenty of advantages over other cities — Cessna and Learjet are still headquartered there, among hundreds of other manufacturers — and Wichita State, in turn, has plenty of related advantages over other schools. But this Innovation Campus can help bridge whatever gap had developed between gown and town. Bardo said he guesses will be finished within the next decade. By 2027, other major manufacturers are expected to join Airbus as tenants, many of them with little to do with aerospace.

Tellier described the whole thing as “an experiential learning center,” and it is. Any place where teens and 20somethings can work with the newest tools, where companies can come develop prototypes, where massive working drones are on display in the lobby, is most definitely established on experience.

It’s also a new way to experience learning, and if it really works, other schools will try to fly just as high.

Virtual reality glasses inside the 3DEXPERIENCE Center at Wichita State. / Matt LaWell, IndustryWeek

LEARN WITH NASA ENGINEERS: College seniors have already started to walk across the stage this graduation season, but some will continue their educations — and they certainly will if they wind up working as NASA engineers. NASA is sending some of its engineers to Collier Research for summer training classes to brush up on the latest in composite materials.

“Composites design optimization is a skill best mastered with hands-on training from experienced instructors who support active learning on-site,” Collier Research president Craig Collier said. “The tools are becoming increasingly user-friendly, but there’s still no substitute for active learning under the direct guidance of a professional.”

The five-day course focuses on HyperSizer software, which was commercialized out of NASA back in 1995, and will be held near Newport News, Virginia. And no, you do not have to be a NASA engineer to attend. The course is open to experts and novices alike — provided you can shell out the $2,500 registration for one spot, or $5,000 for three spots for folks from the same company.

Taro Karibe, Getty Images

ROBOT OF THE WEEK: We’re skipping an actual robot this week to share some really heartening news: According to new figures from the industry trade group Robotic Industries Association, North American robotics companies posted record orders and shipments in the first quarter, up 32% and 24%, respectively year over year. I mean, that sounds really impressive, right? Some other big numbers: Orders from North American companies totaled 9,773 robots valued around $516 million (8,824 robots were shipped, with a value of about $494 million). Orders by automotive OEMs increased 32%, and orders by automotive component suppliers increased 53%. The industry with the biggest jump? Arc welding, up 102%.

AUTOMATION M&A TRENDING UPWARD: The annual global spend on automation systems has increased by more than 140% since the turn of the century — from about $60 billion in 2000 to about $155 billion last year — according to a new whitepaper from Harris Williams & Co.’s Industrials Group. That increase has, in turn, sparked some strong acquisition activity: automation M&A activity grew more than 4% in terms of compounded annual growth rate from 2009 through last year.

Stratasys

WALK THIS WAY: There have to still be a few things that can’t be improved with 3-D printing, but the list is growing shorter just about every day. Stratasys Direct Manufacturing, the on-demand 3-D printing offshoot of the company, announced Monday that it’s working with Peacocks Medical Group to maximize the tech for large-scale production of custom orthotics. (Peacocks is a medical equipment supplier and developed Podfo orthotics.) As someone who suffered through almost a year of plantar fasciitis in both feet and resorted to literally crawling from room to room for a while, count me as one of many people who wishes this was available years ago.

Thinkstock, Getty Images

ODDS AND ENDS: According to research firm Parks Associates, more than 100 million American households are still without a smart home device. (To which I ask: That’s all? I figured the number was a lot higher, but maybe that’s because I live in a 93-year-old home that had been owned by the same family for more than seven decades.) … Berkeley, California-based Bonsai announced Wednesday that it had raised another $7.6 million in its A round, bringing its total to $13.6 million. What the heck is Bonsai? The company automates the management of machine learning libraries and algorithms, enabling businesses to program AI models to increase automation and improve efficiency. ABB, Siemens and now Microsoft Ventures are all investors. … On Monday, the manufacturing consulting firm Factora announced it joined the GE Digital Alliance Program in its continued effort to deliver IoT solutions and improve efficiency on the plant floor. The move allows for more collaboration with GE’s digital tools, tech and domain experience, most notable Predix. (Full disclosure: Factora CEO Charles Horth writes a regular column for IW.)

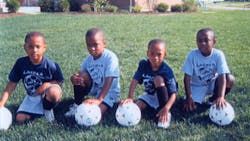

Kim Wade

QUOTE OF THE WEEK: “Discipline and structure. Lots of push-ups and sit-ups and running.” — Darrin Wade, senior staff software architect for General Electric, on how he and his wife, Kim, raised their quadruplet sons, who announced earlier this week they were all matriculating to Yale.

You would have had to have avoided all media last week to miss the story of the Wade quadruplets — 18-year-old Zach, Nick, Nigel and, finally, Aaron all announced they were heading from Lakota East High School near Cincinnati to Yale after receiving offers from a combined 59 colleges — but it’s still incredible and incredibly fun. (Believe it or not, they’re the second set of quads to all enroll at Yale just since 2010.) According to NBC News, Aaron wants to study artificial intelligence, Nigel will study neuroscience, and Zach is thinking of studying chemical engineering. Nick seems to be the only one who doesn’t want to land in the pages of IW; he’d like to be a diplomat.

About the Author

Matt LaWell

Staff Writer

Staff writer Matt LaWell explores news in manufacturing technology, covering the trends and developments in automation, robotics, digital tools and emerging technologies. He also reports on the best practices of the most successful high tech companies, including computer, electronics, and industrial machinery and equipment manufacturers.

Matt joined IndustryWeek in 2015 after six years at newspapers and magazines in West Virginia, North Carolina and Ohio, a season on the road with his wife writing about America and minor league baseball, and three years running a small business. He received his bachelor's degree in magazine journalism from Ohio University.