New Material to Enhance Carbon Capture Technology Discovered

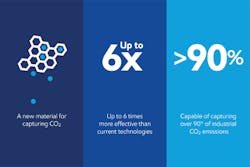

A new material that could capture more than 90% of CO2 emitted from industrial sources, was discovered by scientists from ExxonMobil, University of California, Berkeley and Lawrence Berkeley National Laboratory.

Using less energy to capture and remove carbon, the material has the potential to reduce the cost of the technology and eventually support commercial applications.

Laboratory tests indicate the patent-pending materials, known as tetraamine-functionalized metal-organic frameworks, capture carbon dioxide emissions up to six times more effectively than conventional amine-based carbon capture technology.

By manipulating the structure of the metal-organic framework material, the team of scientists and students demonstrated the ability to condense a surface area the size of a football field, into just one gram of mass – about the same as a paperclip – that acts as a sponge for CO2.

“This innovative hybrid porous material has so far proven to be more effective, requires less heating and cooling, and captures more CO2 than current materials,” said Vijay Swarup, vice president of research and development at ExxonMobil Research and Engineering Co. in a statement on July 24. Since 2000, ExxonMobil has invested $10 billion in projects to research, develop and deploy lower-emission energy solutions.

ExxonMobil’s team, led by senior research associate Simon Weston, along with UC Berkeley’s professor Jeffrey Long and his team of faculty and students have been working collaboratively for eight years to develop this potential carbon capture solution that demonstrates stability in the presence of water vapor, without oxidation, allowing carbon dioxide to be captured from various sources, under a number of conditions.

Additional research and development will be needed to progress this technology to a larger scale pilot and ultimately to industrial scale.

The research successfully demonstrated that these hybrid porous metal-organic materials are highly selective and could capture more than 90% of the CO2 emitted from industrial sources. The materials have a much greater capacity for capturing carbon dioxide and can be regenerated for repeated use by using low-temperature steam, requiring less energy for the overall carbon capture process.

About the Author

IW Staff

Find contact information for the IndustryWeek staff: Contact IndustryWeek