Head First: Smart Helmet Redefines Industrial Wearables

DAQRI is purposely named after the blended drink, but instead of strawberries or bananas, the company mixes realities with its Smart Helmet. Employing a combination of cameras, computer vision, and sensors, this supercharged wearable, which doubles as a hard hat, allows users to see their surroundings in an entirely new and utterly optimized way,

The headgear looks like it was ripped from a sci-fi movie prop department, appropriate considering it can give the wearer a glimpse into the future.

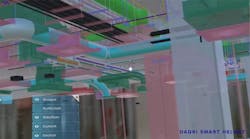

Equipped with high-tech electronics, sensors, and several cameras, the hard hat, which began development in 2014, can superimpose images over the real world, enabling users to see the location of ductwork or electrical cabling hidden within walls.

Recently, by pairing the head mounted display with Autodesk's BIM360 Integration, the Mortenson Construction workers adding mechanical, electrical and plumbing to a hospital project could stand in a barren concrete room and visualize the final installation based on the 3D-modeled blueprints overlaid in the environment.

"I was in awe," says Bryan Bornetun, a virtual design and construction manager at Parson Electric who worked on the project. "Instead of being stuck in the virtual reality world, you can see the walls, you can walk the jobsite, you can see what's in real life at the time, and look up and see the future."

For engineers, leveraging augmented reality to realize plans previously relegated to a computer monitor or tablet could reduce many of the headaches and extra work associated with fitting several systems into the same confined space.

"They're going to be able to see a lot of the collisions that are above ceilings, and situations that fall within the walls," says Mortenson superintendent Terry Johnson. "I think that's going to help them immensely getting ahead and catch those issues early."

Here's a video of the case study:

The Smart Helmet's applications extend well beyond large-scale planning and construction, and it's features can improve virtually any industrial job with the following features:

- Data Visualization to give workers distributed information and situational awareness outside of the control room to improve efficiency by reducing the amount of movement and the need for a centralized location.

- Thermal Vision to create a safer environment for workers by giving them the ability to visualize, passively record, and analyze temperature data in their real world environment. This improves equipment maintenance and monitoring.

- Guided Work Instructions to provide workers with intuitive augmented instructions on the job so they’ll understand processes quickly, spend less time on each step, and make fewer errors.

- Remote Expert to remotely assist workers, by enabling them to see their colleague’s point of view and elevate their skill level. Both the expert and the onsite team member will be able to address issues quickly.

There are tools and tablets to separately accomplish the above, of course. None make you look like a futuristic superhero, and you'll need the use of your hands at some point.

"Hands-free operations reduce distractions, improves safety and enables workers to better focus on tasks," says Matt Kammerait, DAQRI's vice president of product marketing.

A Boeing and Iowa State study found that AR instructions reduced job times by 30% compared to 3D instructions on a tablet. The group also had 94% fewer errors.

Applications span industries ranging from construction to manufacturing to the oil and gas industry, according to the company. The helmet can be programmed using the company’s 4D Studio software, which enables users to use drag-and-drop models to create custom work instructions and data visualizations. The software supports 2-D and 3-D images, audio, and video files, making it possible for anyone wearing the smart helmet to see that information superimposed over their view of the world.

"Hands-free technology provides for greater efficiency in completing tasks and managing workflows," Kammerait says. "We have worked on Proof of Concepts (POCs) with Emerson, Parker Hannifin, Autodesk and Vinci just to name a few."

As a parallel offering to DAQRI Smart Helmet, 4D Studio software is provided for customers to create interactive AR experiences and publish them to the helmet. You can create custom work instructions by adding images, documents, text or videos for easy reference in the field.

Participation in the DAQRI early adopter program is $15,000, and includes DAQRI Smart Helmet Developer Edition, 4D Studio software and apps (remote expert, data visualization, thermal vision and guided work instructions).

Our west coast NED rep, Emily Capaccioli, tried the Smart Helmet out last month at Autodesk University in Las Vegas. Here’s what she thought:

First Impressions? “It’s very futuristic in appearance. Think Tom Cruise in Minority Report.

How was the fit? “The helmet wasn’t as large as I expected, with the amount of technology that is built into it. It’s similar in weight to a batter or moto helmet. Since I have a somewhat small head, I was worried it would not fit me. However, it has a strap that adjusts with the turn of a knob to make sure the helmet fits properly, no matter the size.”

What was the demo like? “It showcased the integration with Autodesk’s Fusion 360. The visor is tinted to allow video and augmented reality to appear as you perform your daily job. However, you are able to easily distinguish the two. During the demo, we were able to experience augmented reality and view ductwork inside the building we were in.”

If you were selling it, what would your pitch be? “It elevates any workforce by being able to reduce issues that wouldn’t necessarily be easily seen. The product should be on every plant manager/decision makers list who is looking to increase productivity, and work more efficiently with real time information.”

This article originally appeared on NED. New Equipment Digest is a companion site of IndustryWeek and part of Penton's Manufacturing and Supply Chain.