Siemens Sees Atlas 3D as Part of Additive Manufacturing Puzzle

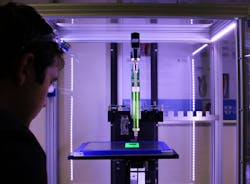

From day one, 3D printing was supposed to provide an easy avenue for companies to create anything. Unfortunately, potholes in the road have made it difficult from most firms to easily transition designs from small runs to useful production parts.

The high rate of 3D print failures is a key challenge companies face in leveraging additive manufacturing for high-volume production. Parts often need to go through several design and analysis iterations before the optimal build orientation and support structures are determined. Typically, designers don’t have the capabilities to consider such factors as part orientation, distortion, and heat extraction uniformity in their design. This puts the onus on engineering specialists to resolve such issues.

Sunata software, created by Plymouth, IN-based Altas 3D, aims to solve this problem by giving front-end designers a quick, easy and automated way to get much closer to a “right first time” build. Sunata is a GPU-accelerated high-performance computing additive manufacturing software solution that can deliver results up to one hundred times faster than other build simulation solutions on the market. GPU-accelerated computing is the employment of a graphics processing unit (GPU) along with a computer processing unit (CPU) to facilitate processing-intensive operations such as deep learning, analytics and engineering applications.

Joining Siemens

Siemens signed an agreement to acquire Atlas 3D Inc. as part of Siemens Digital Industries Software, where its solutions will expand additive manufacturing capabilities in the Xcelerator portfolio of software. Atlas' Sunata software that works with direct metal laser sintering (DMLS) printers to automatically provide design engineers with the optimal print orientation and requisite support structures for additive parts in near real-time.

Sunata software uses thermal distortion analysis to provide a simple, automated way to optimize part build orientation and generate support structures. This approach allows the designer—rather than the analyst—to perform these simulations, thereby reducing the downstream analysis that needs to be conducted via Simcenter software to achieve a part that meets design requirements.

Siemens plans to make the Atlas 3D solution available through its online Additive Manufacturing Network.

“We welcome Atlas 3D to the Siemens community as the newest member of our additive manufacturing team. Our solutions industrialize additive manufacturing for large enterprises, 3D printing service bureaus, design firms and CAD designers,” said Zvi Feuer, Senior Vice President, Manufacturing Engineering Software of Siemens Digital Industries Software. “The cloud-based Sunata software makes it easy for designers to determine the optimal way to 3D print parts for high quality and repeatability. The combination of Sunata with the robust CAE additive manufacturing tools in Simcenter enables a ‘right first time’ approach for industrial 3D printing.”

“The power of Sunata is that it equips designers to more easily design parts that are printable, which helps companies more quickly realize the benefits of additive manufacturing,” said Chad Barden, Chief Executive Officer of Atlas 3D. “As part of Siemens, we look forward to introducing Sunata to customers who already have Siemens’ AM solutions and can achieve new efficiencies in their front-end design-for-additive process, as well as companies who have yet to start their additive manufacturing journey.”

About the Author

IW Staff

Find contact information for the IndustryWeek staff: Contact IndustryWeek