Design Thinking: Human-Centered, Data-Driven Manufacturing

In manufacturing, data is often referred to as the “new oil,” but this analogy falls short in one critical way: Oil must be refined before it has value. Similarly, raw data alone can’t drive results; it requires careful processing to extract actionable insights. This is where design thinking comes into play—a human-centered, problem-solving approach that helps manufacturers turn complex data into practical solutions.

For manufacturing leaders navigating challenges such as supply chain disruptions, operational inefficiencies and workforce adaptation, design thinking offers a new way to approach decision-making. By focusing on empathy, creativity and iteration, this methodology bridges the gap between advanced technology and real-world applications.

What Is Design Thinking

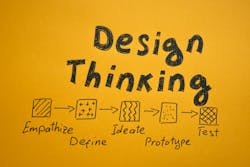

A structured, five-step approach to solving problems:

- Empathize: Understand the needs, frustrations, and challenges of the people involved, whether they’re operators on the shop floor, logistics teams or customers.

- Define: Articulate the problem clearly, using insights from step one.

- Ideate: Brainstorm creative solutions, often involving cross-functional input.

- Prototype: Create testable versions of the solution to gather early feedback.

- Test: Iterate and refine the solution until it meets operational goals effectively.

What sets design thinking apart is its focus on human needs. Instead of starting with the tools or technologies available, it begins by asking, “What problem are we solving, and for whom?” This mindset ensures that solutions are not only technically robust but also practical and widely adopted.

Why Manufacturing Needs Design Thinking

Manufacturing is inherently complex, with competing priorities such as reducing downtime, improving quality and managing costs. Design thinking helps leaders navigate this complexity by focusing on the human side of problems. This approach ensures that solutions are grounded in real-world workflows and operational constraints.

For example, during the COVID-19 pandemic, supply chain disruptions challenged manufacturers worldwide. Traditional forecasting tools failed to account for sudden, unprecedented changes in consumer demand. Design thinking provided an alternative approach, emphasizing collaboration with stakeholders to identify creative strategies like substitutable products, optimized inventory allocation and real-time data adjustments.

Making Digital Twins More Effective

Digital twins—virtual models that replicate physical systems—are becoming essential tools in modern manufacturing. They allow leaders to simulate operations, test changes and predict outcomes. However, the success of digital twins depends on how well they address the practical needs of their users.

Design thinking ensures digital twins are built with usability and adaptability in mind:

- Empathy for Users: Before creating a digital twin, identify the specific challenges faced by its users. For example, a plant manager might need a tool to simulate production line adjustments, while a supply chain leader may prioritize visualizing inventory flows.

- Iteration and Feedback: Early prototypes should be tested with stakeholders to ensure they provide actionable insights. This prevents costly revisions down the road.

- Clear Visualization: Complex data must be presented in a way that decision-makers can quickly understand. For example, a digital twin could use heat maps to highlight bottlenecks or simulate the impact of supply chain disruptions.

By focusing on these elements, digital twins become not just technical marvels but practical tools for improving efficiency and resilience.

Translating Business Needs into Technical Solutions

A persistent challenge in manufacturing is the gap between technical teams and operational leaders. Data scientists, for instance, may focus on building sophisticated models, while plant managers are concerned with real-time results.

Design thinking addresses this disconnect by encouraging collaboration and introducing the role of an “analytics translator.”

Analytics translators bridge the gap between technical expertise and operational needs. They ensure that projects align with organizational priorities and that solutions are practical for end-users. For example, in a factory with frequent equipment breakdowns, a translator might help data scientists develop a predictive maintenance dashboard tailored to operators’ needs—simple, mobile-accessible and actionable.

Building Resilience in Supply Chains

Supply chain disruptions, whether caused by natural disasters, pandemics, or geopolitical tensions, remain a top concern for manufacturers. Design thinking provides a framework to anticipate and address these disruptions by fostering collaboration and creative problem-solving.

Consider a manufacturer facing raw material shortages. Design thinking could guide the team to:

- Collaborate with suppliers to identify alternative materials.

- Work with production teams to adjust workflows for substitutability.

- Apply cross-industry inspiration, such as using demand-based pricing models from the financial sector to allocate limited inventory.

By focusing on the human elements of these challenges—such as understanding how operators and customers will be affected—design thinking ensures solutions are both innovative and actionable.

Practical Benefits

Design thinking also provides practical tools for prioritizing projects. For example, using a benefits-versus-effort matrix, leaders can identify “quick wins”—initiatives that deliver high value with minimal resource investment. This approach helps manufacturing teams focus on projects that provide measurable results while avoiding overinvestment in less impactful solutions.

Moreover, the iterative nature of design thinking supports a “fail fast” mindset. Early prototypes allow teams to identify issues and pivot quickly, saving time and resources. For example, a pharmaceutical company using design thinking during COVID-19 was able to rapidly test and implement inventory strategies based on substitutable products, ensuring supply continuity without disrupting operations.

Strategic Imperative

Design thinking is more than a methodology—it is a strategic imperative for manufacturing leaders. In an era of rapid change, it enables organizations to:

- Anticipate challenges and respond with agility.

- Align technological investments with human needs.

- Foster collaboration across departments and industries.

As disruptions become more frequent and supply chains grow more complex, manufacturing leaders must adopt approaches that balance innovation with practicality. Design thinking provides the tools and mindset to navigate these challenges effectively.

For manufacturing leaders, the value of design thinking lies in its ability to humanize data science and bridge the gap between technology and operations. By starting with empathy, focusing on usability, and iterating solutions, this approach turns raw data into actionable insights and real-world results.

In today’s interconnected and unpredictable world, adopting design thinking is not just a competitive advantage—it is a necessity.

About the Author

Raj Mahalingam

Raj Mahalingam is a seasoned data scientist with over a decade of experience, specializing in leveraging design thinking, data science and machine learning algorithms to address complex data challenges. His expertise spans multiple domains, including procurement, e-commerce, pricing, logistics, warehousing, inventory optimization and supply chain resilience.

Raj worked extensively in the pharmaceutical and semiconductor industry, where he played a pivotal role in navigating supply chain disruptions during and post COVID-19 pandemic. He developed innovative solutions for inventory management, demand forecasting and supply allocation, ensuring critical product availability during unprecedented times. He currently works at Intel Corp.