High-Performing Port and Workforce Training Drive Global Manufacturing in South Carolina

Last week I had the opportunity to spend two days visiting the Charleston, S.C., metro area as the guest of the Charleston Regional Development Alliance (CRDA). Claire Gibbons, director of Global Marketing & Communications, was my hostess, and told me that if you drew a line along the 32nd parallel across the U. S. from San Diego, you would wind up at Charleston. Like San Diego, Charleston is a major port, being the deepest port along the south Atlantic coast, able to handle ships with up to 48 foot draft, depending on tides. Charleston is about 50% lower in population than San Diego (761,000 versus 1.407 million [2016]), but is growing 3X faster than the U.S. average (14.5% versus 4.7%).

Charleston is a military town like San Diego and is home to Joint Base Charleston, one of twelve joint facilities operated by the Department of Defense; the U.S. Space & Naval Warfare Systems Center Atlantic (SPAWAR), one of the Navy’s only two cyber mission engineering centers; and nearly all U.S. Dept. of Defense and Dept. of Homeland Security agencies. These facilities represent more than 23,000 active duty, civilian and contract civilian personnel.

Our first stop on my visit was the South Carolina Ports Authority (SCSPA), where we met with James Newsome, III, president and CEO. He said “Charleston meets the needs of today’s global shipping industry, particularly as large vessels are deployed to East Coast trade routes. Our South Atlantic location is a significant driver of the Port of Charleston’s above-market average cargo volume growth, offering proximity to the fastest growing population in the U.S., as well as a booming manufacturing economy.”

He said, “We just received approval to dredge to a 52-foot depth to be able to handle the new, larger container ships that are coming online. Two new taller cranes just came online (155 feet vs. 115 feet), and we have two more on order to install in 2018. We are also raising four existing cranes, for a total of eight cranes offering 155 feet of lift height. We have three active cargo terminals now, and a new terminal is in development on the former Navy base. One of our terminals is a drive off terminal for automobiles, and the other two handle container ships. The new terminal will also handle container ships. The larger container ships are 13,000 TEUs in capacity. We also built a new rail connection from Charleston to the Inland Port in Greer to able to reduce truck congestion at the port and expedite rail shipments out of the region.

As we drove around the terminal that has the new cranes, I was dismayed to see thousands of containers from Chinese and German shipping lines, but was encouraged when Newsome said that according to the latest report, Charleston is the port that is the most balanced in terms of imports and exports on the Atlantic coast. The port is also seeing good growth in exports of manufactured goods. The three terminals turn over the entire number of containers every 7-10 days.

Newsome said, “Charleston ships more tires than any other port in the United States. Michelin came in the 1970s and has invested $6-7 billion in their manufacturing facilities. BMW came in 1994 and has invested about $10 billion in their facilities. About 70% of BMWs are shipped out of the Charleston port from the entire line made in the U. S. Boeing built a plant in 2009. Mercedes-Benz Vans is building their new Sprinter vans here. Volvo will open a new $500 million facility near Ridgeville in 2018. Five companies represent about 70% of our shipping volume.”

After I returned home, I found this important data on the port’s website: “A 2015 study by the University of South Carolina’s Darla Moore School of Business concluded that the port’s statewide impacts include:

- $53 billion in annual economic activity

- 187,600 jobs

- $10.2 billion in labor income

- 10 percent of total annual gross state product

- $912 million in tax revenue”

Besides cars, tires, and other manufactured goods, Newsome said that the major products shipped out of Charleston are: agricultural (soybeans, grains), forest products (including diaper pulp), poultry and pork.

According to the SCSPA website, the five fast-growing business sectors for the port are:

- Automotive manufacturing

- Consumer goods distribution

- Refrigerated/frozen exports

- Transloading resin & grain

- Tire manufacturing & distribution

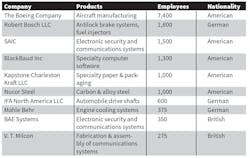

Charleston shares some of the same industry clusters that San Diego has: aerospace, information technology, and life sciences. Their other two largest industry clusters are automotive and logistics. The following chart derived from data on the CRDA website shows the top 10 manufacturers ranked by number of employees:

On our drive to our next appointment, I asked Claire to fill me in on the South Carolina business climate, so I could understand why so many foreign companies have established plants in the state. She said, “South Carolina offers a strategic location, particularly for companies based in Europe, and a business-friendly climate. We are a “right to work” state with no corporate income tax.” There are other benefits shown on the CRDA website: “no state property tax, no local income tax, no inventory tax, no sales tax on manufacturing machinery, industrial power or materials for finished products, no wholesale tax, and no unitary tax on worldwide profits.”

Claire added that another big advantage is that when a company relocates or expands to South Carolina, they can get training at little to no cost for their employees through readySC, a division of the South Carolina Technical College System. ReadySC’s mission is to “To promote the economic and workforce development of the state of SC. We provide customized training for new and expanding business and industry in the state of SC…”

Later in the day, I had the opportunity to visit the Mercedes-Benz Vans Training Center, where I met with Terrance Rivers, area director of readySC, Susan Pretulak, vice president, Economic Development of the SC Technical College System, and Alyssa Bean, responsible for communications at Mercedes-Benz Vans manufacturing plant.

Pretulak said, “The Division of Economic Development works to not only attract new and expanding companies to the state but also provide the workforce development tools necessary to make certain they grow and prosper in South Carolina over the long term. The division is touted as providing a comprehensive solution for companies looking to grow their workforce in South Carolina. Housed within the division are the system’s nationally renowned statewide programs — readySC and Apprenticeship Carolina.”

She explained, “Training is state-funded and is open to companies who will hire 10+ new, permanent, full-time employees with benefits. There is a simple two-page agreement to participate in the program. We have 16 technical colleges in our system, and each college has a readySC group. We are working with 89 companies at present. We have two programs: (1) Pre-hiring Training, which is an unpaid training experience to provide potential employees for a company client and (2) Post-hiring Training, which is job specific training, such as welding, machining, assembly, etc.”

I asked if they have developed their own curriculum or do they use the SME ToolingU curriculum, and she said, “Some of both.” Rivers said. “We have a three-phase program: Design, discovery, and delivery to customize the training to meet a company’s needs. Daimler was one of our first clients before they switched their name to Mercedes-Benz Vans. They make the Sprinter van at their plant.”

The readySC website expands on the requirements to participate in the program, specifying: To qualify, we require that:

- Jobs projected must be permanent

- Pay represents a competitive wage for the area

- Benefit package must include health insurance

- Number of jobs created must be sufficient enough to allow readySC to provide training in a cost-effective manner

Pretulak informed me that the SC Technical College System is also responsible for the Apprenticeship Carolina program, which “works to ensure all employers in South Carolina have access to the information and technical assistance they need to create demand-driven registered apprenticeship programs. At no cost to the employer, apprenticeship consultants are available to guide companies through the registered apprenticeship development process from initial information to full recognition in the national Registered Apprenticeship System.

The program started with 90 apprenticeship programs in 2007, and now has 918 programs today, representing 14,475 apprentices. One in three participating employers offer programs in more than one occupation. The target industries are: advanced manufacturing, construction technologies, energy, health care, information technology, and tourism and service industries. The total number of apprentices trained to date is 26,864, and the program is averaging more than 120 new apprentices per month.

At dinner that evening, I met Robin Willis, associate vice president, Talent Pipeline Strategies for the Charleston Metro Chamber of Commerce. She said, “We are very proud of the growing number of Youth Apprenticeship students and their hosts in our region. We feel strongly that this program provides life changing experience for students and helps companies fill their critical talent needs, so much so we have funded the program in its entirety. There are 105 youth apprentices currently in the workforce – 66 new ones that started in August 2017 and 39 who started their 2nd year in August 2017 and will complete the program in June 2018.

I told everyone that I haven’t visited any other state that has such comprehensive training and apprenticeship programs, and I am very impressed by what South Carolina has to offer to existing and relocating companies. It is no surprise that so many foreign companies are choosing South Carolina to establish or expand their U.S. presence. Other states (particularly California) would be smart to emulate the business incentives and training programs offered by South Carolina.

About the Author

Michele Nash-Hoff

President

Michele Nash-Hoff has been in and out of San Diego’s high-tech manufacturing industry since starting as an engineering secretary at age 18. Her career includes being part of the founding team of two startup companies. She took a hiatus from working full-time to attend college and graduated from San Diego State University in 1982 with a bachelor’s degree in French and Spanish.

After graduating, she became vice president of a sales agency covering 11 of the western states. In 1985, Michele left the company to form her own sales agency, ElectroFab Sales, to work with companies to help them select the right manufacturing processes for their new and existing products.

Michele is the author of four books, For Profit Business Incubators, published in 1998 by the National Business Incubation Association, two editions of Can American Manufacturing be Saved? Why we should and how we can (2009 and 2012), and Rebuild Manufacturing – the key to American Prosperity (2017).

Michele has been president of the San Diego Electronics Network, the San Diego Chapter of the Electronics Representatives Association, and The High Technology Foundation, as well as several professional and non-profit organizations. She is an active member of the Soroptimist International of San Diego club.

Michele is currently a director on the board of the San Diego Inventors Forum. She is also Chair of the California chapter of the Coalition for a Prosperous America and a mentor for CONNECT’s Springboard program for startup companies.

She has a certificate in Total Quality Management and is a 1994 graduate of San Diego’s leadership program (LEAD San Diego.) She earned a Certificate in Lean Six Sigma in 2014.

Michele is married to Michael Hoff and has raised two sons and two daughters. She enjoys spending time with her two grandsons and eight granddaughters. Her favorite leisure activities are hiking in the mountains, swimming, gardening, reading and taking tap dance lessons.