In 2022, 364,000 jobs were reshored (up 53% from 2021), according to the Reshoring Initiative. The reasons for this new growth were threefold:

· Manufacturers are nervous about relations with China and are bringing production back to the U.S.

· Biden administration initiatives—the Inflation Reduction Act, the Infrastructure Bill, and the Chips Act—have offered both direction and financial security for companies willing to invest in American manufacturing.

· Third, tariffs are working. A good example is the Section 232 tariffs for the steel and aluminum industries.

Reshoring is moving in the right direction, but at its current rate, it will take over 30 years to reach President Joe Biden’s goal of 5 million new manufacturing jobs.

Critical Industries

The Biden/Harris administration has a goal to develop and implement advanced manufacturing technologies, grow the advanced manufacturing workforce and build resilience into manufacturing supply chains. These are just generalizations, but to have any chance of success, they need to focus on saving and growing the critical manufacturing industries.

I have been following the 38 manufacturing industries listed in the Bureau of Labor NAICS database, which shows changes in employment and business establishments in 38 industries. Up until 2021, all 38 industries were declining in terms of both the number of establishments and employees. However, since 2021, most industries show growth in establishments and employees.

Eleven are critical industries fundamental to the manufacturing process and to making other manufactured products. The good news is that 10 of these critical industries are growing again in terms of employees—the outlier being tool and die making.

These industries are critical to all other manufacturing industries. They include the highly skilled artisans that make the jigs, fixtures, dies, molds, cutting tools and gauges used in the manufacturing process. They also include the process of making parts by pouring metal to make a casting, the making of steel and aluminum used in all of these processes, and industries that make the parts for other products. However, Table 1 also shows that machine shops, tool and die, nonferrous foundries continue to decline in terms of total establishments.

Skilled Worker Training

The passage of the Chips Act and the Inflation Reduction Act and the success of reshoring has led to a new demand for skilled workers. However, more skilled workers are retiring than are being replaced, and there is no longer a pool of skilled workers to draw from.

The problem of a shrinking supply of skilled workers has been known for 30 years. In May of 2023, the Department of Labor (DOL) Job Openings and Labor Turnover Survey (JOLTS) showed 608,000 unfilled manufacturing jobs. A study by Deloitte and the Manufacturing Institute (MI) predicts that U.S. manufacturing will have 2.1 million unfilled jobs by 2030.

The training programs to produce highly skilled workers are few and far between and multinational corporations are not investing in long-term, high skill training like apprentice training. A January 2020 training survey by the Manufacturing Institute shows that the average number of hours of training, per employee, among its members (mostly large corporations) is 27.7 hours per year. For new employees, it was 42.9 hours per year. The training survey also shows that only 32% of members have apprentice training programs.

Multinational corporations, with few exceptions, are not investing in advanced training that takes thousands of hours in areas such as machining, tool and die, and mold-making. The study says that “75% of industrial organizations identified reskilling the workforce as important or very important for their success over the next year, but only 10% said they were very ready to address this trend.” The 27.7 hours per year seems to indicate that the Manufacturing Institute’s members are not going to invest in training the highly skilled employees they need for the future.

If we are going to save and grow the 11 critical industries, then we will need advanced or long-term apprentice training to train the machinists, tool and die makers, mold makers, forging and foundry workers that are fundamental to the manufacturing processes.

This problem won’t be solved by a couple of classes at a community college or buying software training programs. What is needed are training programs that lead to journeyman status and take thousands of hours—and most of the skills are attained with hands-on learning, not classroom learning. An example is a journeyman machinist, which takes approximately four years or 8,000 hours to attain the 28 skills needed to become a journeyman on a wide variety of manual and CNC machines.

If multinational corporations are not willing to invest in the long-term skills training to develop and train the skilled workers than the only answer may be government as described in President Bidens Build Back Better initiative.

Dollar Value

The root cause of the trade deficit and the primary reason that our exports are not price-competitive is because the dollar is overvalued by 20 to 40%. We have been using lean processes and continuous improvement for decades, but it hasn’t reduced manufacturing costs enough to make our exports competitive.

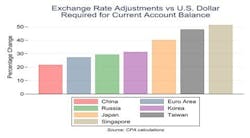

A study by the Coalition for a Prosperous America in February 2022 illustrates why currency imbalances hurt America’s competitiveness. Chart 2 shows the persistent dollar misalignment against seven countries. U.S. producers are trying to compete with these countries, operating at a disadvantage of 20% to 40%. So the obvious conclusion is unless we can do something to reduce the value of the dollar, American efforts to increase exports are doomed to fail. The inconvenient truth is that we will never be able to increase exports or create Biden’s 5 million manufacturing jobs as long as our prices are artificially high.

I don’t see any alternative but to steadily reduce the value of the U.S. dollar. One approach would require the Federal Reserve to impose a “market access charge“ on foreign investments in the United States. This tax would cover asset purchases including stocks, bonds, real estate, or intellectual property – pretty much everything foreigners might want to buy, except for goods to be exported. The stated objective is to achieve a current account balance within five years

According to a CPA/Federal Reserve model, realigning the dollar by 26% would balance the current account and reduce the trade deficit to zero “

America has finally reached a point where there is a great opportunity to reshore both industries and jobs. If the Biden Administration is serious about creating 5 million manufacturing jobs, it will need to focus on the critical industries that are fundamental to the manufacturing process, invest in apprentice training and devalue the dollar.

Michael Collins is the author of Saving American Manufacturing and The Manufacturers Guide.