So That Happened: The Continuous Improvement Way Back Machine, Smart Manufacturing Goes to College

Editor’s note: Welcome to So That Happened, our editors’ takes on things going on in the manufacturing world that deserve some extra attention. This will appear regularly in the Member’s Only section of the site.

Smart Factories, College Edition

Calling it a “smart factory” in the press release seems a little overblown considering we’re talking about some lab and studio spaces in a college building, but Purdue Polytechnic Institute announced a five-year partnership with the professional services company Accenture to create a learning center for smart technologies.

The idea of creating a “smart manufacturing workforce” is kind of interesting, considering one of the questions I always come across is whether operators take to or are turned off by smart technologies on the floor. The answer is invariably something along the lines of “A little at first but now they love it and want more.” But it would be better to just skip that first part and get straight to the second.

Purdue offers an undergraduate major in smart manufacturing industrial informatics so the partnership on their side makes sense. Accenture gets to promote its digital engineering and manufacturing service, Industry X, and one imagines their drawing some future employees out of Purdue.

The coolest part of the story is a new Women in Manufacturing scholarship that ostensibly includes the equivalent of in-state tuition every year for up to four years just like the larger Accenture Smart Manufacturing Scholars Program created via the partnership.

Manufacturing Opportunities for People with Visual Impairments

With its wide array of jobs, manufacturing companies have increasingly become more flexible in finding ways for people with various challenges to find jobs in their operations.

With this in mind, and to entice students who are visually impaired to consider careers in manufacturing and engineering, a competition with be held on Dec.2-4 at the Kansas State School for the Blind (KSSB).

The competition is created by Make48, which is a makers community that creates events across the country.

The student-led event is for students ranging in age from 12 to 21 years old -- who are blind or have low vision. The first event of its kind, 20 students will be broken into six teams and will have 48 hours to solve a challenge that directly impacts the visually impaired community.

These teams will work with Make48 tool technicians to create an innovative product prototype. To develop the prototype the students will have access to the KSSB Makerspace where they can use 3D printers, embroidery circuit machines, heat press and more. They will also produce a promotional video and sales sheet and will then present their idea to a panel of judges.

This effort, and hopefully others to come, will address the issue of unemployment among those who are blind. According to the Bureau of Labor Statistics, nearly 7 in 10 working-age Americas who are blind are not employed.

Steel Showdown Looms

Cleveland-Cliffs Inc. on Nov. 28, hiked the base prices of their hot rolled, cold rolled and coated steel products by at least $60 per ton. A day later, U.S. Steel executives followed suit. The moves came three months after Cleveland-Cliffs and other steel companies instituted a price increase of $75 per ton.

But that first increase didn’t take at all in the face of an economy that’s softening in some corners: From late August until Cleveland-Cliffs announcement this week, the per-ton price of hot rolled steel fell nearly 20% to about $660, and it has given up a little ore ground since. And that’s coming from a price above $1,500 as recently as March, the result of a massive run-up as the economy restarted in the summer of 2020.

Argus reported that market players don’t expect these hikes to make big waves, either, but that they may bring some stability as steel makers look to set a floor going into next year. On his Q3 conference call a month ago, Cleveland-Cliffs CEO Lourenco Goncalves was confident in his 2023 pricing power, saying that auto companies “we deal with in January tend to be a little more reasonable” and that recent renegotiations with other OEMs had gone to Cleveland-Cliffs’ satisfaction.

“They know that we are not bluffing.”

But Goncalves may no longer have that leverage: Wolfe Research analyst Timna Tanners recently said falling spot prices look set to give OEMs the muscle to negotiate 2023 prices that are 20% to 30% lower. We’ll know soon enough which way the market winds are blowing.

In Search of 80-Year-Old Efficiency Ideas

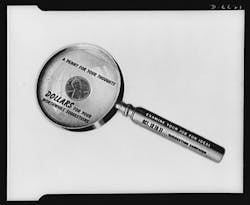

Many manufacturing plants converted from peace-time activities to war-time production during the timespan during which this photo was taken, as World War II raged. Given the source of this photo, I assume this facility was among the converted.

I can't find much information to explain this picture beyond what is shown and what the Library of Congress has shared. Described as a "suggestion stimulator," the company's request for ideas was inserted into the pay envelopes of RCA Manufacturing employees. This particular suggestion campaign ran from the middle of October to the end of that month.

Did the request for suggestions relate specifically to war-time production or did RCA Manufacturing routinely look to its employees for improvement suggestions? If the latter is the case, that seems enlightened thinking. How much could one earn by providing ideas for improvement? And did the earnings increase if an idea was implemented?

Finally, the big question: Were campaigns like this a success in the 40s? These days the idea of providing monetary rewards is a controversial one, with some saying such rewards undermine continuous improvement and others saying the opposite. (Here’s another take on the topic.) The right answer is likely somewhere in the middle.

Personally, I'm pleased to read that the company sought ideas from its employees. As for the rest on the unknowns about this photo, I think my curiosity is doomed to go unsatisfied.

About the Author

Dennis Scimeca

Dennis Scimeca is a veteran technology journalist with particular experience in vision system technology, machine learning/artificial intelligence, and augmented/mixed/virtual reality (XR), with bylines in consumer, developer, and B2B outlets.

At IndustryWeek, he covers the competitive advantages gained by manufacturers that deploy proven technologies. If you would like to share your story with IndustryWeek, please contact Dennis at [email protected].

Geert De Lombaerde

Senior Editor

A native of Belgium, Geert De Lombaerde has been in business journalism since the mid-1990s and writes about public companies, markets and economic trends for Endeavor Business Media publications, focusing on IndustryWeek, FleetOwner, Oil & Gas Journal, T&D World and Healthcare Innovation. He also curates the twice-monthly Market Moves Strategy newsletter that showcases Endeavor stories on strategy, leadership and investment and contributes to other Market Moves newsletters.

With a degree in journalism from the University of Missouri, he began his reporting career at the Business Courier in Cincinnati in 1997, initially covering retail and the courts before shifting to banking, insurance and investing. He later was managing editor and editor of the Nashville Business Journal before being named editor of the Nashville Post in early 2008. He led a team that helped grow the Post's online traffic more than fivefold before joining Endeavor in September 2021.

Jill Jusko

Bio: Jill Jusko is executive editor for IndustryWeek. She has been writing about manufacturing operations leadership for more than 20 years. Her coverage spotlights companies that are in pursuit of world-class results in quality, productivity, cost and other benchmarks by implementing the latest continuous improvement and lean/Six-Sigma strategies. Jill also coordinates IndustryWeek’s Best Plants Awards Program, which annually salutes the leading manufacturing facilities in North America.

Have a story idea? Send it to [email protected].