It's been more than 20 years since the word "lean" entered the manufacturing lexicon, which may explain why rumblings of "What comes after lean?" or "What's next now that I've finished lean?" bubble to the surface with some regularity.

Two decades. Such questions seem reasonable after that length of time, until you take a closer look at lean's aim. The Lean Enterprise Institute describes lean's core idea this way: "to maximize customer value while minimizing waste." Moreover, says the institute founded by James Womack—whose early work advanced lean production ideas—the ultimate goal of a lean organization "is to provide perfect value to the customer through a perfect value creation process that has zero waste."

Perfection. It's tough to achieve or sustain, which explains why continuous improvement is tightly intertwined with any discussion about lean. It also explains why lean is never "done."

Despite never being done, lean isn't standing still. New ideas, new technologies and next moves continue to propel the lean movement. Here are a few examples.

Horizontal Thinking is a Work in Progress

Lean's origins are largely inside manufacturing's order fulfillment process, encompassing manufacturing, distribution, transportation and inbound supply chain, says Robert Martichenko, CEO of LeanCor and author of "Building a Lean Fulfillment Stream." The emphasis has been on turning organizations, which typically are structured vertically, to the horizontal, hence terms like flow and value stream.

However, "In the last two years, I think there's been a recognition by organizations that there is only so far you're going to go if you only focus on order fulfillment" or the physical flow aspects of the organization, Martichenko says. Such organizations are beginning to recognize that decisions made at the overall business strategy level, in product development, and in sales and marketing are driving waste and variation into the order fulfillment function, he says.

Martichenko's not suggesting that lean thinking is absent from product development, sales and marketing, or overall business strategy. Indeed, he acknowledges the opposite is true. "That whole idea of 'doing lean,' it's been populated into everything and anything," he says.

However, taking lean into different functions is still functionally—or vertically—focused within the whole, he points out.

About 12 months ago, Martichenko said his company took time to reflect on the outcomes of his company's work with various clients. Some of the results were fantastic; others were less so. One conclusion his organization drew was that its interactions primarily were with the order fulfillment part of the organization. Meanwhile, decisions that impacted the order fulfillment processes were made elsewhere and not in any collaborative way.

"We realized we were not going to get to the next step by just focusing on order fulfillment. We had to go to the other three parts of the business," he says.

That's where LeanCor is today—getting more of the business functions to the table for more collaborative decision-making. Getting the leaders of the various functions involved has been happening with more and more success, he says.

"The challenge is that when we start to talk about the business decisions that are driving waste into the order fulfillment process, we realize that these business decisions aren't being made because people are mismanaging or people are purposely trying to drive waste. They are actually making decisions based on principles and goals and performances they are trying to get in their functional area," he says.

What's needed, he says, "is an overall mental model change."

"Most organizations have either a sales-and-marketing-centricity, or they have a finance-centricity, or they have a product development-centricity. What we're saying is, 'Hey, what if you ran your business with a supply chain-centricity?' That your business decisions were all being made to support that horizontal flow in the supply chain," he says.

Leading Edge or Back to Basics?

Then there's the story of the manufacturing company most frequently associated with lean: Toyota Motor Corp. and its Toyota Production System. In late March, the Japanese automaker announced TNGA, or Toyota New Global Architecture, which it called "a comprehensive approach to achieving sustainable growth by making ever-better vehicles more efficiently."

The next month Toyota announced it would build a new plant in Mexico—its first TNGA plant—and expand a joint venture in China that would exploits the TNGA innovations.

While many press reports surrounding Toyota's announcement centered on its shared parts strategy and new vehicle platforms—and associated cost reduction—the thinking behind the doing is equally compelling.

The end game, explained Toyota President Akio Toyoda during an investors' meeting, is to develop smarter ways to build cars that customers want. "Ever-better cars" was the common refrain. Toyoda described the new business model (via an interpreter) as "a framework for reassessing every activity, from planning, design and parts procurement to production, in order to build attractive cars that people all over the world feel they'd love to own."

"A key phrase we are using here is simple and slim," he said, in outlining the way plants will change. Elements of the new look include compact equipment installed directly on the plant floor rather than within the floor or suspended from the ceiling; and smaller paint booths and production lines that can be easily lengthened or shortened as demand dictates. These innovations, Toyota estimates, will help reduce initial plant investments by 40% compared with 2008 levels.

Additionally, Toyota says the goal behind its integrated vehicle development approach, including the strategic sharing of parts and powertrain components, is a 20% or more reduction in resources. The capital gained, or saved, via the streamlining, as well as new technologies and work processes, will be reinvested into developing "ever-better cars," according to Executive Vice President Mitsuhisa Kato.

Let's not forget the human element. "What development sites and production sites share is the recognition that the most important thing is trusting the human ability to think and thoroughly train oneself. I believe that what has supported Toyota's growth up to now has been our people," Toyoda said. "It is the people who always try to improve how things were done in their workplaces and continuously implemented new ways and methods."

So, is Toyota onto something new, or improving upon the gold standard?

"In our view, the announcement of TNGA, and related breakthrough innovations is Toyota at its best," wrote Jeffrey Liker, author of "The Toyota Way," and Jim Morgan in a blog post on the Lean Enterprise Institute website. "It represents the true meaning of the Toyota Way—deliberate innovation to deliver ever-greater customer value through detailed and rigorous collaboration between product development engineering, suppliers and manufacturing."

They continue, "This has been the philosophy of product-process development for over a decade and reflects a return to the basics of the Toyota Production System."

Lean is 3-D at Eaton

Then there's Eaton Corp.'s Kings Mountain plant, located a short distance from Charlotte, N.C. The facility, which employs about 400 workers, produces transmissions for the North American heavy-duty truck market. It has won both internal and external awards for manufacturing excellence, including the North Carolina Shingo Prize for Excellence in Manufacturing and an Eaton Business Excellence Award.

A tour of the facility reveals a significant embrace of lean and continuous improvement tools and methods, including empowered work teams, visual controls, gemba walks, cellular manufacturing, 6S and leader standard work.

Oh, and 3-D printing.

You might not immediately think about 3-D printing as an improvement tool, but it now has a place in the toolbox at the Kings Mountain site.

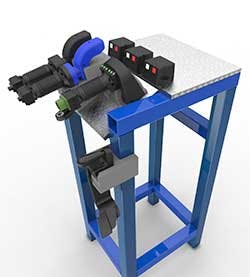

Senior manufacturing engineer Alex Abernethy came up with the idea to give 3-D printing a try while creating a plan to automate a process that previously had been performed manually. The problem—or challenge—was the nature of the fixture required to make the whole scheme work.

The fixture included small, intricate details that would have been nearly impossible to machine, Abernethy explained. And even had the plant been able to find a shop that could machine the thin-walled detail features, it would have been both an expensive and time-consuming endeavor.

Seeking alternatives, Eaton met with a local distributor of 3-D printers, who made a test print. "We were impressed and that was the start of it," says Travis Beert, manufacturing engineering manager.

Following that initial success, Abernethy—and Eaton—began using the 3-D printer in a wide array of improvement efforts, starting with poka yoke devices for manual assembly areas. "Alex can quickly print a prototype versus something that might take 10 to 12 weeks if sent out to a machine shop," Beert notes.

The 3-D printer also has been used to make safety devices. For example, the engineer created a plastic guard to protect the hands of assemblers who use mauls in their work. Additional uses include maintenance components and 5S organizational tools.

Moreover, the 3-D printer gives Eaton the ability to quickly modify a design, a key advantage, Beert and Abernethy say.

When a printed tool wears out, for example, "I review the design, see the weakness, tweak the design and make enhancements," Abernethy says. He also describes an occasion where he sent the 3-D printer a design wirelessly from a hotel room on a Saturday, and on Monday it was ready for use when he returned to the plant.

Promoting Collaboration

The introduction of 3-D printers at Eaton's Kings Mountain site (the facility now has a second, larger one for bigger pieces) has promoted additional lean behaviors, such as increased engagement. Beert says the printers generate significantly more interaction with the operators, who are more inclined to provide feedback and make design requests, he said.

Collaboration between engineering and the plant's internal machine shop on designs and improvement ideas has increased as well, says Abernethy.

Furthermore, the collaboration extends beyond the Kings Mountain site. Beert says other Eaton plants have taken an interest in the 3-D efforts taking place in his facility and have purchased or are considering purchasing printers of their own. Not only that, but the plants are sharing knowledge. For example, a sister Eaton plant recently showed Kings Mountain a tool it created to avoid a set-up on a machine. Beert says, "We may be able to do the same thing, with some modifications."

Don't Look Ahead Too Soon

For most companies implementing lean, it's too soon to ask, "what's next?" "Companies have been practicing elements of lean for decades now, and the general consensus is that 95% of those that try are not truly lean," says Jerry Solomon, recently retired from MarquipWardUnited, where he was vice president of operations. "One of the reasons is that most companies just focused on the easier tools rather than the much more encompassing elements. They have mostly ignored the most important pillar of lean, which is respect for people. That is why culture is the most talked about topic at all lean conferences I have attended these last few years."

Rather than, What's next after my lean journey," the better questions perhaps is: What's next in my lean journey? Enterprising firms continue to make advances.

About the Author

Jill Jusko

Bio: Jill Jusko is executive editor for IndustryWeek. She has been writing about manufacturing operations leadership for more than 20 years. Her coverage spotlights companies that are in pursuit of world-class results in quality, productivity, cost and other benchmarks by implementing the latest continuous improvement and lean/Six-Sigma strategies. Jill also coordinates IndustryWeek’s Best Plants Awards Program, which annually salutes the leading manufacturing facilities in North America.

Have a story idea? Send it to [email protected].