Proactive Problem-Solving Decants a Bourbon-Bottle Mystery

On factory floors and in production facilities across America, manufacturing leaders face relentless pressure to increase output while reducing costs. When quality issues, equipment failures, or production bottlenecks arise, the traditional response is often to identify which employee made a mistake. However, there’s a better solution: empowering employees at all levels to become proactive problem solvers who continuously improve the production system itself.

The foundation of this approach lies in a profound manufacturing truth: approximately 94% of production problems stem from system issues rather than operator errors. Yet many plant managers continue playing "the blame game”—searching for guilty employees instead of addressing underlying process, equipment or material variables that are the real root causes.

Systems Thinking: the Foundation of Proactive Problem-Solving

Effective problem-solving begins with recognizing that work is a result of interconnected components forming systems. When employees actively participate in improving these systems, they first focus on their immediate work. As they mature in their approach, they recognize the interdependent nature of processes and initiate collaborations that create meaningful improvements across departments.

Systems are easy to visualize in manufacturing settings—raw materials, equipment, production rates and defects are tangible. However, modern manufacturing increasingly involves "human work systems" as well—networks of interactions and handoffs of information designed to create desired outcomes. These systems often exist as informal procedures without documentation, resulting in high variation and inconsistent results.

Making Systems Visible: The First Step Toward Improvement

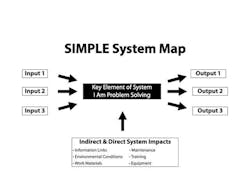

You can't improve what you can't see. A fast and effective way to make your system visible is creating a simple flowchart showing the key component you're examining, along with inputs and outputs. Label the center of your diagram with the specific step or component you're addressing. From the left, list components that impact your area. To the right, list outputs resulting from your center component. Above and below, list indirect factors affecting your work—information links, environmental conditions, materials, maintenance, training and equipment.

This quick visualization helps identify potential problem factors and makes the invisible visible.

Understanding Variation: Common Cause vs. Special Cause

Everything in life has variation – people, equipment, materials, processes. Two distinct types of variation impact systems:

Common cause variations are built into the system itself and occur regularly. Examples include inconsistent raw materials, equipment performance fluctuations or variations in employee training methods.

Special cause variations result from mistakes or random breakdowns outside normal operation—like an employee who was distracted and skipped a step, a once-in-a-century flood or a global pandemic disrupting supply chains.

Finding Root Causes: The Five Whys Technique

When problems are identified, effective leaders dig deep for root causes rather than blaming employees. The "Five Whys" technique involves repeatedly asking “why “until reaching the true root cause.

Consider this manufacturing example:

Q: WHY did employees damage expensive parts?

A: They weren't properly trained on handling procedures.

Q: WHY weren't they properly trained?

A: We use informal worker-to-worker training, which isn't consistent.

Q: WHY do we use informal training?

A: Developing proper training is expensive.

Q: WHY is it expensive to develop?

A: We don't have documented standard operating procedures.

Q: WHY don't we have written documentation?

A: Because it wasn't considered valuable before now.

This exercise reveals that the root problem isn't careless workers but a lack of standardized procedures and training—entirely within management's control to fix.

The Carbonless Paper Breakthrough

A classic example of the power of system improvement occurred years ago at the Nashua Corporation when my father worked there. Management initially blamed workers for production problems with carbonless paper. However, when the director of central engineering measured system variation across raw materials, equipment, procedures and training, he discovered that coating viscosity varied significantly between barrels, forcing operators to constantly adjust machine settings.

By working with suppliers to standardize coating viscosity, the company saved the equivalent of $4 million in today's dollars from one machine alone. The critical insight: The variation was entirely outside worker control. No matter how diligently they worked, each barrel of raw material represented an unpredictable challenge.

The Bourbon Bottle Mystery

At my own Brain Brew Distillery, we spent six frustrating months trying to solve inconsistent fill levels in custom bourbon bottles. Despite exhaustive troubleshooting of innovative bottling technology, the problem persisted.

The breakthrough came when we questioned assumptions and tested the bottles themselves. By measuring identical volumes in different bottles, we discovered the cause: variation in the bottles from different manufacturing molds.

The lesson? Even experienced problem-solvers can waste months looking in the wrong places when they fail to consider all possible system variables.

From Breakdown to Breakthrough: The Bottling Line Story

When a high-speed bottling line was installed at the Brain Brew Distillery to meet surging demand, reliability problems threatened production. The line broke down every six minutes on average, creating enormous frustration.

Initially, our team focused on "cases shipped"—an outcome too abstract for effective problem-solving. They refocused on reducing breakdowns per hour, divided the machine into four modules, tracked breakdown types in each and tackled one module at a time.

This targeted approach yielded dramatic results. Breakdowns fell from 10 per hour to just one to two per hour within weeks. As it turns out, the root causes of the problems were a half dozen small things that were not set properly when the machine was installed. For example, the brushers that pushed the tamper evident capsules were set too high, causing shut downs, and the grippers for holding the bottles needed to be adjusted. It was a case where many small things multiplied on themselves to create a big problem. More importantly, our team developed a problem-solving mindset that prepared them for future challenges.

The Never-Ending Journey of Improvement

When a senior vice president at Brain Brew asked when the system would be "fixed and finished," my response was emphatic: "NEVER!"

As long as competitors strive to create something better, improvement must be continuous. Organizations that stop improving face the same fate as trees and oysters that stop growing: They die.

By empowering employees as proactive problem-solvers and teaching managers to recognize system issues rather than blame individuals, organizations break free from the blame game. They create cultures where continuous improvement becomes part of everyone's job, resulting in enhanced quality, reduced costs and a more engaged workforce. In today's competitive environment, this capability isn't just an advantage – it's increasingly a requirement for survival.

Main Photo: Doug Hall, right, and Joe Girgash, founders of Brain Brew Distillery.

About the Author

Doug Hall

Founder, Eureka Ranch and Brain Brew Distillery

Doug Hall, author of Proactive Problem Solving, is the founder of Eureka! Ranch and Brain Brew Distillery. He has been named one of America’s top innovation experts by Inc. magazine, The Wall Street Journal, Dateline NBC, CNBC, and CIO magazine. A hands-on inventor, Hall helps businesses, governments and nonprofits find, filter and fast-track big ideas.

His earlier books include the bestselling Jump Start Your Brain, Driving Eureka! and Jump Start Your Business Brain. A chemical engineer by education, Hall was Master Marketing Inventor at Procter & Gamble – shipping a record nine products in 12 months. For his pioneering work in innovation, Hall was awarded a Doctor of Laws from the University of Prince Edward Island and a Doctor of Engineering from the University of Maine.