How Vulnerable Is Your Supply Chain?

The elements of supply chain confidence are visibility and control, the lack of which will increase supply chain risk.

“Visibility” refers to the ability of all members of a chain to see from one end of the pipeline to another; an undistorted view not clouded by intermediate inventories or other barriers to vision. Lack of visibility forces supply chain members to rely on forecasts and to build buffers, worsening the situation.

Unfortunately today most supply chain members do not have detailed knowledge of what is happening in the rest of the chain. For example, they usually lack information on finished goods inventory, material inventory, work-in-process, demand levels, production plans, capacity, yields and order status.

Supply chain control refers to the ability to respond to disturbances in appropriate ways. Problems arise when disturbances are not recognized in time and when there is a time lag for the remedial action to take effect. This can result in the remedial action actually worsening the situation.

The factors identified above are present, to a greater or lesser extent, in most supply chains today. For this reason it is apparent that organizations need to be aware of where there are vulnerabilities in their supply chains that create risk and how they can manage or reduce risk wherever possible.

Supply Chain Visibility

Supply chains have become increasingly vulnerable to disruptions, from natural disasters to the global credit freeze.

The natural disasters over the past two years (2011 and 2012)—which include the Japanese earthquake and tsunami, the massive flooding in Thailand, the earthquakes in Italy, and the recent flooding on the eastern seaboard of the United States—illustrate the potential for supply chain disruption at anytime.

The need for real-time demand-supply visibility is clear. Without supply chain integration, information about demand and supply takes days, weeks or even months to be communicated across the supply chain. This time lag causes demand signals to be amplified, as one moves further away from the ultimate source of demand, the end customer. This is what’s known as the bullwhip effect.

There is an increasing requirement for a single, shared view of customer demand. Much work has been completed over the past ten years in “leaning” out supply chains. As a consequence of driving efficiency improvement, many supply chains have lost the flexibility to respond to fluctuations in demand in a timely manner.

Building agility happens through conscious choice. It requires joint planning, mutual trust and aligned incentives between the various members of the supply chain. Brand owners who focus exclusively on standard product cost, rather than total landed cost, will find it difficult to build agile supply chains.

Organizational agility improves when organizations focus on four things:

- the definition of a clear supply chain strategy

- the building of strong decision support analytics (ability to model scenarios to understand volatility impacts)

- the implementation of strong horizontal processes to sense and translate demand and supply

- building collaborative relationships between supply chain members based on trust, transparency and joint profitability.

It has to be a conscious choice. Just as an athlete makes a choice to do strength training followed by flexibility exercises, the supply chain needs to recognize the need and build the right design to ensure agility.

Supply Chain Agility

Before further discussing supply chain visibility, let’s first review the topic of supply chain agility, since this is one of the primary business drivers for a more integrated approach to supply chain management, and that equals improved supply chain visibility.

Supply chains are substantially less agile than five years ago. They are more brittle and less resilient. Many of the programs driven by the first-generation pioneers (tight integration of the supply chain, lean process improvement programs, eProcurement and electronic bidding) made the supply chain stronger; but for many, there was an unconscious trade-off in reduced agility.

Interestingly, there is no consistent industry definition for agility. While companies frequently use the term, and quickly acknowledge the need, the term needs to be defined by each organization. For a market-driven supply chain, one of the most appropriate definitions of agility is the design of the supply chain to have the better cost, quality and customer service for a given level of demand and supply volatility.

Many supply chain practitioners are looking to improve agility focus on cycle-time reduction, while maintaining a focus on continuous quality improvement, as there are no prizes for doing the wrong things faster.

Surveys indicate that while companies see agility as an important goal, few have the prerequisite agility they feel are needed run the race. There is a large gap between current importance and performance.

Companies are increasingly focusing on improving the resiliency of their supply chains to mitigate this risk. Companies such as Intel, P&G and Unilever are building improved multi-tier supply chain visibility and advanced network management capabilities to be agile in the face of these disruptions.

Given that it is value chains, and not individual companies, who compete in today’s market-place, there is an increasing requirement for supply chain collaboration and visibility (see Figure 1).

Shortening of product lifecycles is creating ever increasing pressure on supply chains to dynamically adjust and adapt to overall business strategy. The strategy is most affected by uncertainty in both demand and supply for certain types of markets. For example, consider a market where innovations are very high and manufacturing processes are evolving. Adding agility to supply chains and utilizing technology for information sharing, coordination and adopting principles of postponement will likely produce promising measures.

At Flextronics, we are pursuing a comprehensive approach to providing our customers with end-to-end supply chain visibility, offering our global customer base an integrated supply chain platform. We believe the solution resides in collaborating with our supply chain partners, utilizing the right set of tools and capabilities to integrate the extended network.

This automated, integrated platform is designed to provide for the monitoring of supply chain performance, the dynamic updating of supply allocations plans, and the ability to sense and respond to demand changes.

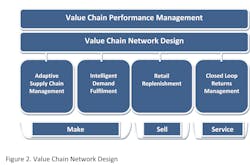

Flextronics’ technology platform is designed to fulfil these critical requirements while at the same time providing a blueprint for transforming the supply chain into a competitive differentiator (see Figure 2).

Flextronics system focuses on the four key areas:

- Adaptive Supply Management.This solution provides a system capability to proactively respond and adapt to demand fluctuations and priorities by manipulating supply decisions. The solution solves supply imbalances through dynamic supply orders and inventory actions.

- Intelligent Demand Fulfillment.This solution enables proactive monitoring, management and control across order and product fulfilment decisions. It allows resolution of customer order conflicts through order prioritization and other fulfilment dimensions (location, substitution, etc.).

- Retail Replenishment.This solution provides the capabilities necessary to monitor demand at individual retail stores (or other forward finished goods stocking locations), establish appropriate target inventory levels to balance risk of stockouts vs. overstocks, and maintain target inventory levels through efficient replenishment.

- Closed Loop Returns Management.This solution provides visibility and analytics—beginning with the pre-qualification process and extending across device support specialists/assisted sales, remote support and diagnostics, as well as repair and disposition.

A Face-Off between Rival Supply Chains

Competing in today’s global economy is fast becoming a face-off between rival supply chains. The dilemma that most brand owners face is quite daunting: How can you quickly serve customers with a varied and dynamic product line-up, while also ensuring that your outsourced supply chain is running at the lowest possible total cost?

The solution to a large extent involves the integration of the various parts of today’s global supply chain across a common data platform and the establishment of more collaborative business relationships between supply chain members. This common platform should provide near real-time visibility to physical flows, while putting in place a number of proven logistical strategies and techniques to increase network flexibility and responsiveness.

At Flextronics, we have had the privilege of helping a number of global brand owners and original equipment manufacturers (OEMs) revamp their supply chains by implementing proven strategies for more seamless operations and improved customer service. Based on the requirements of our customers, we have established product completion centers to enable efficient localization, and building consistent global return and repair processes. Along the way, we collected a large number of best practices which we have leveraged to build an integrated solution for our customers. As this playbook demonstrates, the Flextronics solution offers the unique advantage of an integrated set of planning capabilities that can quickly and reliably take your value chain to the next stage of operational performance and profitability.

Caroline Dowling is president, Integrated Network Solutions wjth Flextronics, a $30 billion, Fortune Global 500 electronics manufacturing services and end-to-end supply chain solutions provider with more than 200,000 employees and operations in 30 countries. In this role, she leads an international team focused on design, manufacturing and services providing end-to-end solutions worldwide for the telecom, networking, server and storage markets.