Four Steps to Supercharging Sustainable Battery Manufacturing

As battery manufacturing expands to meet the demand for electrification, new manufacturing startups continue to emerge, and legacy manufacturers are shifting their product development pipelines. These organizations are guided by sustainability goals driven by customer expectations and, in some cases, encouraged by government incentives. However, too many companies take a tactical approach to sustainability by developing disconnected demonstration projects, such as random bioswales, partial monitoring of energy consumption, or small solar fields. While these are often well-intentioned efforts, they are ineffective over the long term.

A better approach is to craft an overall sustainability strategy that includes a comprehensive evaluation of a company’s battery supply chain, from sourcing raw materials to recycling.

Developing a sustainable battery manufacturing strategy involves four key steps:

1. Embracing a Holistic View

Everything has a cost, whether it is economic, environmental (deforestation), or social (community impact). Solutions are not sustainable if you drive down economic costs at the expense of significant environmental damage or negative social impacts. Similarly, it is not sustainable to prioritize environmental or social results at exorbitant economic costs.

For instance, early in the design phase of a battery cell plant, a client requested that their facility be powered entirely by solar panels. While solar panels are useful in many situations, they do not generate enough energy per square foot to power a battery manufacturing plant effectively. If we covered every inch of the plant roof with solar panels, we would still need 525 acres of solar panels to power the plant. Tripling the required acreage of the plant and converting 525 acres of farmland that currently captures carbon into a solar field is not sustainable. After a discussion with our client, they agreed, leading us to develop alternate strategies that included purchasing sustainable power through the utility provider combined with a comprehensive plan to reduce overall utility usage in the plant.

2. Being Open and Honest

It is critical to be transparent about the realities of the current situation. For example, studies have shown that at the time of manufacturing, EVs have twice the negative environmental impact of comparable internal combustion vehicles. EVs only begin to reach a break-even point once they are being driven. Even then, the source for charging determines how quickly the break-even point is reached, which can range from 9,000 miles when charged with 100% renewable energy to almost 90,000 miles when charged by a coal-fired plant. (When do electric vehicles become cleaner than gasoline cars? | Reuters)

In manufacturing, as well as charging, sustainability is often driven by the source of power. Taking a holistic view, is a battery truly sustainable if the manufacturing process is driven by a coal-fired plant or depends on horrific working conditions in third-world countries? Clearly, the source of energy, as well as the sources of manufacturing materials, must be considered in sustainability discussions.

3. Considering the Entire Battery Ecosystem

Sustainability opportunities exist throughout the battery ecosystem—from mining and material processing to cell manufacturing, applications, recycling, and reuse. Even if we do not have direct control of portions of the battery ecosystem, we all have influence. Using this influence to source services and materials from organizations and locations with strong environmental requirements and labor laws can improve the sustainability of the entire system. As part of an overall sustainability strategy, it is up to industry leaders to understand the value chain and then drive sustainable practices within it, using their influence to encourage others to do the same.

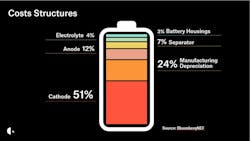

4. Examining Cost Structures

To identify where the impact can be greatest, it is essential to consider all cost structures. These costs may not always be monetary, but for the purposes of this discussion, we will use reducing costs as a proxy for increased sustainability.

Battery costs significantly impact the overall cost of an EV. The two largest drivers of that cost are cathode active materials (CAM) (51%) and manufacturing (24%), which together account for 75% of total battery cost. Focusing on the two largest cost components:

CAM (51%)

Three areas of improvement that will reduce the costs and increase the sustainability of CAM are:

- Localizing material processing: For example, LG Chem is building a CAM facility in Clarksville, Tennessee. Once in operation, this CAM will replace material being imported into the U.S. The new CAM will be manufactured with relatively clean power, under strong environmental controls, and within a few hundred miles of their customer.

- Improving extraction practices: Recent advancements in mining processes have reduced the negative impacts traditionally associated with battery material extraction. This includes the adoption of waterless extraction methods and the utilization of more sustainable feedstocks, as can be seen in the cleaner production methods for CAM. There's a Better Way to Mine for Electric Vehicle Batteries | Scientific American

- Optimizing battery chemistry (the holy grail): Advances in battery chemistry, such as the development of sodium-ion and next-gen lithium-ion technologies, are leading to more sustainable and efficient batteries. These innovations reduce reliance on scarce and costly materials like cobalt and nickel while maintaining or even improving performance. Next-gen battery tech: Reimagining every aspect of batteries - Ars Technica

A lot of activity in both North America and Europe will bring CAM production closer to its point of use. Once complete, these production plants will shorten supply chains and produce CAM, using more sustainable energy sources under stricter environmental regulations. We need to strongly support these projects.

Ideally, raw materials for CAM can be extracted near existing production facilities. Where that is not possible in the U.S. in the near term (due to permitting and other constraints), the industry must use a holistic sustainability lens and support sustainable mining practices in other parts of the world.

Finally, it is essential to acknowledge that current batteries are simply not good enough. The holy grail is to move away from rare-earth metals altogether and develop battery chemistries that use common earth materials.

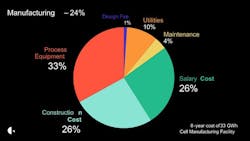

Manufacturing (24%)

The next largest piece of a battery’s cost is manufacturing. Looking at projected data over an eight-year period for a 33-gigawatt-hour (GWh) cell manufacturing operation, more than half the total cost is related to construction, salary costs, and utilities (see graphic above).

Several strategies can drive sustainability by improving the long-term efficiency of plant operations. These include:

Water Reuse Opportunities

In our research, we have found that if manufacturers plan for water reuse during the design phase of their project, they can use stormwater capture from rooftop runoff to significantly reduce water intensity without increasing carbon emissions. The resulting payback period for stormwater capture is four years and net neutral emissions.

Identifying key sustainable impact areas at the start. Sustainable battery manufacturing requires early planning, coordination, and goal setting. Some sustainability strategies, such as using a highly efficient chiller plant, are straightforward. Others, like capturing and reusing waste heat from the charge/discharge process, can have a significant impact if the return on investment (ROI) problem can be solved.

ROI analysis should include both direct and indirect costs for the implementation of each sustainability scenario. Direct costs include capital, operations and maintenance (O&M), and engineering and life cycle. Indirect costs include operational and embodied carbon impacts of implementation and their resiliency impacts. The carbon footprint of each scenario can be calculated using a life-cycle assessment to find the subsequent greenhouse gas emissions.

The resulting ROI can then be evaluated holistically based on the direct cost payback periods, indirect costs represented by the carbon footprint, and resiliency factors (compared to a baseline scenario).

Streamlining process flow. A commonly overlooked piece of the sustainability puzzle occurs during a project's initial organizational and budgeting phase. Separate process and facility teams often operate as two different organizations with separate budgets and limited communication. This can cause optimization of the parts at the expense of the whole, leading to increased costs, schedule overruns, and reduced operational efficiency. A focused integration effort and the use of tools to enhance communication—such as 3D modeling, virtual whiteboards, and team-building exercises—is critical.

Utilizing prefabrication. Prefabrication is inherently sustainable because it allows major plant components to be built off-site in a controlled environment, reducing waste, improving construction, and enhancing quality. Combined with 3D building information modeling (BIM) virtual design and construction (VDC) tools, prefabrication can reduce all costs across the board—economic, environmental, and social.

Leveraging benchmarking. Benchmarking enables informed questioning of the overall scale, utility demands, and environmental data before the design phase begins. By gathering data from similar projects, tools can be developed to contrast and compare different operations. This information can then be used to evaluate a plant’s efficiency by comparing a series of metrics against production goals.

Looking Forward

To be genuinely sustainable, we have to do better. Evolving battery chemistries, improving technologies, and shortening supply chains are moving us in the right direction. By adhering to these four broad principles, the battery manufacturing industry can live up to its aspirations and pave the way for a sustainable future.

About the Author

David Verner

David Verner is executive vice president of Gresham Smith's Industrial market. He has more than three decades of experience working with national and international clients on designs for a variety of building types in diverse markets including advanced manufacturing, automotive, and FDA regulated facilities.