America Needs a Manufacturing Strategy

Opinion/Analysis

Supporters of American manufacturing have been crying for a national manufacturing strategy for many years. They know that if the U.S. does not have a plan with measurable objectives, nothing will change and we won’t re-industrialize America.

The first compelling reason to develop a plan is that our competitors have manufacturing plans and strategies that have allowed them to successfully export to the U.S. In fact, China’s “Made in China 2025” plan spells out exactly which industries and technologies they want to dominate in the future. Why can’t we develop a plan?

Second, the Bureau of Labor Statistics shows that 38 manufacturing industries are declining in terms of establishments and employment. We need a strategy to stop the erosion of our manufacturing base and specify which industries are critical and need to be saved.

Third, we need to prevent the loss of high value-added manufacturing sectors like the advanced technology industries.

Why can’t we develop a plan?

A Commitment

But before designing a plan with specific manufacturing strategies, the government needs to first publicly commit, in writing, to saving American manufacturing. President Joe Biden has made a big deal out of his plan to “ensure the future is Made in America by all of America’s workers.” The President wants to create manufacturing jobs and grow the manufacturing sector. But to achieve his goals, he will have to find ways to reduce the trade deficit by stopping currency manipulation and decreasing the value of the dollar.

When asked about the dollar and currency manipulation, Biden’s new Treasury Secretary Janet Yellen said she believed “markets should set the value of currencies and that we would not seek a “weaker currency to gain competitive advantage.”

All past administrations also began with lofty goals about growing manufacturing, but when it came time to do something to reduce the trade deficit and stop currency manipulation, the Treasury Department always chose to keep the dollar strong. Subsequently nothing changed.

The government must get its act together, speak with one voice, and say exactly how they will bring back manufacturing. As long as the dollar is over-valued, there is no reason for American manufacturers to invest in the U.S., and every reason to move their production to low-cost foreign countries.

President Biden has publicly issued goals increasing manufacturing employmentby 5 million jobs, strengthening unions, investing in infrastructure and protecting

some industries. But to turn his goals into a reality, he needs to develop a plan that, like a business plan, has four different parts—explicit goals, competitive analysis, measurable objectives, and a definition of critical industries that we must save.

The Goals

The primary goals should be to restore U.S. manufacturing to a competitive position in the global economy, increase exports and balance trade. A national manufacturing strategy would not pick winners and losers. We need a manufacturing plan with the explicit goal of stopping the decline of manufacturing in terms of plants and employees in 38 industries, and state that we are willing to stop currency manipulation and reduce the trade deficit to make it happen.

Competitor Analysis

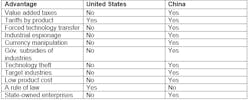

Every good business plan that I have read does a good job of first doing a competitor analysis that shows competitors’ strengths and weaknesses in a matrix as I described in my book “Saving American Manufacturing.” The reasoning is simple: once you can define competitors’ advantages and your weaknesses, you will know where to change or adopt specific strategies to compete. For instance, here is a brief comparison of the U.S. to China:

This comparison shows that we are trying to compete but have few advantages against the Chinese. To really get a good idea of how competitive we are (or aren’t), we need to add the other 13 trading competitors into a matrix, comparing all of our competitors in these 11 factors.

Measurable Objectives

Just having explicit goals is not enough. To make any plan work, there must be measurable objectives. The third part of the plan is to define clear and measurable objectives so we know how and when we are successful.

Objective 1: 5 million new manufacturing jobs. The plan needs to say how many jobs per year for the next 4 years.

Objective 2: Currency manipulation. The plan needs to say when currency manipulation will be stopped by country and year. It also needs to describe the penalty used such as a market access charge.

Objective 3: Dollar value. The root cause of the trade deficit is an overvalued dollar that is 20 to 30% too high. There is a bill in Congress that would introduce a Market Access Charge to begin the process of balancing our trade. The treasury department should state a measurable objective on how and when they can reduce the value of the dollar per year.

Objective 4: Trade Deficit. The U.S. is heading towards a $1 trillion trade deficit. The plan needs to state the dollar amount of reduction per year, and which year they can expect to balance the trade account

Objective 5: Critical industries. The 38 industries that are declining in terms of lost companies and jobs are listed in the Bureau of Labor database so the plan needs to say which of these industries we are willing to save. It should also say which of the Advanced Technology Industries should be protected.

Objective 6: GDP growth. Manufacturing was 21% of GDP in 1975 but has been slowly eroding for years. It is now 11%. The plan should state the objective for what the GDP % should be in 4 years. If we can make headway in most of these objectives a reasonable objective would be 16% of GDP.

Objective 7: Exports. Increasing our exports is a critical factor in balancing trade. It

should not be a general goal like Obama’s 2010 goal of doubling exports. We need a measurable objective that can be measured year to year in terms of % increases in exports.

Objective 8: Imports. Closely allied to exports, a reduction in imports would also help to attain the objective of reducing the trade deficit and can be measured year to year in terms of % decreases.

Critical Industries

In their Made in China 2025 plan, China’s leaders state they want their country to dominate in environmental technologies, information technology, biotechnology, artificial intelligence, railroad equipment, alternative energy, new materials, electric vehicles, aviation, telecommunications, machine tools, and robotics. China already dominates the computer, cell phone, rare earth elements, auto parts, pharmaceuticals and a wide variety of electronic industries. They have shown in the last 20 years that they will do whatever it takes (legal or illegal) to achieve their objectives.

So, the question is, how can the U.S. prevent China from taking these industries and technologies from the U.S.?

President Biden has said publicly that he wants to protect the semiconductor industry by providing the industry $37 billion in short-term funding. He has also said he will prioritize batteries for electric vehicles, pharmaceuticals, cars, and rare earth. But to have a comprehensive business plan, he needs to investigate the other 38 industries that are declining as well as all 50 of the advanced technology industries, and state which ones are critical and we must save.

Conclusions

Even though re-industrialization and saving American manufacturing are vital to the future of the country, I must also say that there are many people against having a plan or any manufacturing strategies because they want to maintain the status quo. At the top of the list are the multinational corporations and big box retailers—and Wall Street, which finances the deficit. Many corporations have invested in plants in China and Asia to ship their products back to the U.S., and they will be very resistant to any changes that restrict imports or reduce the value of the dollar.

The latest crisis in the semiconductor industry, as well as the COVID-19 crisis that revealed to America that most of our pharmaceuticals and medical equipment are made in China or India, are emblematic of the manufacturing problem. America is a country lurching from crisis to crisis without a plan or even a clear direction.

The latest book by Clyde Prestowitz, “The World Turned Upside Down,” provides the best plan on how to re-organize the government and raise the money to save American manufacturing. This book, particularly the chapter called “The Plan for America,” shows in great detail how we got into the current mess with China and where the U.S. went wrong in its international trade strategy. I highly recommend you get a copy.

Michael Collins is the author of Saving American Manufacturing and can be reached at mpcmgt.net.