Who Let China in? and Supply Chain Cracks Form: 25 in 2025

Manufacturing leaders are always on their feet and always busy. It’s tough to keep track of the daily news cycle, let alone reflect on the past. Before the first quarter of the 21st century slips away, we at IndustryWeek decided to take a closer look at the important people, policy, technology, events and trends over the past 25 years and determine which have been truly gamechanging for manufacturing.

Together with input from IndustryWeek contributors and past editors, the IW editorial staff has assembled our list of 25 Manufacturing Gamechangers since 2000. Told in five installments that we'll roll out over two weeks, it includes some well-known historical items with a manufacturing twist, as well as important developments that have been mostly under-the-radar.

Special thanks to IndustryWeek contributors Jamie Flinchbaugh, Christopher Tang, Carolyn Hendrickson, Warren Browne and Lauren Pittelli and former IndustryWeek editors Pat Panchak and Travis Hessman, who gave us valuable input on the list.

We’d like to hear from our readers as well. Do you have a gamechanger that’s not on the list—or have your own unique list in mind? Or, maybe you just want to relate a memory associated with one of our Gamechangers. Please share with us below.

We hope this series prompts more discussion and reflection about where manufacturing has been, where it is today and where it’s headed.

#1: The US Grants China Most-Favored-Nation Status

In 2000, President Bill Clinton signed the U.S.-China Relations Act, which established China’s permanent most-favored nation status. That paved the way for China’s entry into the World Trade Organization two months later.

Clinton said China’s new status would let U.S. companies “export products without exporting jobs” and promote democracy there, but trade benefits of the arrangement benefited China more, and democracy was a path not taken. In time, entire U.S. manufacturing sectors like apparel, electronics, consumer goods and pharmaceuticals were dismantled and outsourced to China.

This hastened the march of U.S. employment for those without post-high-school education away from manufacturing and toward jobs in the service industries.—Ryan Secard

More Manufacturing Gamechangers

#2: Increased Border Security After Sept. 11 Exposes Supply-Chain Cracks

The September 11, 2001, terrorist attacks on the World Trade Center and Pentagon shook the United States and its place in the world. In the economic aftermath, cracks began to form in the embrace of supply-chain globalization as national security worries that U.S. manufacturing could not support needed defense spending with the outsourcing of key industries took hold.

With heightened concerns at the borders, the newly formed U.S. Department of Homeland Security tightened shipping rules, requiring shippers to submit more advanced package data earlier in the process and setting up container checkpoints at 58 ports across the world. These practices brought more cooperation and visibility into the supply chain and improved efficiency. —Ryan Secard

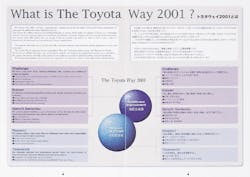

#3: Toyota Formalizes Its Manufacturing Principles in the 'The Toyota Way'

Few manufacturers can claim that their production system has been imitated, adapted or adopted by companies around the globe as the basis for their own operating systems. Toyota Motor Corp. is an exception. Intrigued by the Japanese manufacturer’s success, Western companies starting in the 1970s began investigating and employing Toyota Production System methods, eventually inspiring what is now known as lean manufacturing.

But it was globalization that prompted a new project directed by then Toyota President Fujio Cho: development of the Toyota Way 2001 booklet, which codified the values, philosophies and the “company’s fundamental DNA” in an easy to understand and visual way. Under two main pillars—continuous improvement and respect for people—the pamphlet outlined five key concepts: challenge, kaizen, genchi genbutsu, respect and teamwork.

While the rapid growth of Toyota workers outside of Japan and the desire to establish a common management system among that distributed workforce prompted the Japanese manufacturer to develop the Toyota Way 2001 pamphlet for its employees, external interest in everything Toyota only accelerated. Jeffrey Liker in 2004 released the best-selling “The Toyota Way: 14 Management Principles from the World’s Greatest Manufacturer,” where he notes that Toyota’s pamphlet “greatly influenced” his own thinking of Toyota’s 14 principles. And talk about longevity: The Toyota Way management philosophy continues to influence business practices today.—Jill Jusko

#4: Apple’s iPod Rollout Precedes the Smartphone Revolution

In 2001, Apple kickstarted a new era of consumer electronics with the release of the iPod. It wasn’t the first commercially available digital music player, but it was easier to use and had more storage than competing products. The 6.5-ounce portable device had a 5 GB hard drive, enough to hold around 1,000 songs. The simple and intuitive interface allowed anyone to easily interact with the technology, making it one of the first steps toward an increasingly digital world.

The introduction of the iPod was the first step in Apple’s journey to dominating technology and electronics. Smartphones would go on to become a huge market, necessitating the need for massive production capacity and adding to the global surge in the importance of semiconductor technology.—Anna Smith

#5: EtherCAT Transforms Manufacturing Automation

Without the EtherCAT (Ethernet for Control Automation Technology) communication network, the idea of automating hundreds of multi-axis robot arms simultaneously to reliably manufacture electronics is ludicrous.

Developed by industrial computer (PLC) manufacturer Beckhoff Automation and released in 2003, EtherCAT introduced the capability to automate manufacturing plants with large numbers of network machines by bringing increased speed and accuracy to the reliability of traditional ethernet technology.

Ethernet technology essentially works by breaking data into datagrams that each contain the information required to reassemble that piece of data into the entire file to which they belong. By breaking the data into smaller parts, it flows more quickly over the network. EtherCAT takes that a step further, having time commands associated with it to make it easier to coordinate many machines.

PLCs don’t have time to grab parts of machine command data and reassemble them into whole commands while also keeping in sync with dozens or hundreds of other PLCs on the floor doing the exact same thing.—Dennis Scimeca

About the Author

Jill Jusko

Bio: Jill Jusko is executive editor for IndustryWeek. She has been writing about manufacturing operations leadership for more than 20 years. Her coverage spotlights companies that are in pursuit of world-class results in quality, productivity, cost and other benchmarks by implementing the latest continuous improvement and lean/Six-Sigma strategies. Jill also coordinates IndustryWeek’s Best Plants Awards Program, which annually salutes the leading manufacturing facilities in North America.

Have a story idea? Send it to [email protected].

Laura Putre

Senior Editor, IndustryWeek

As senior editor, Laura Putre works with IndustryWeek's editorial contributors and reports on leadership and the automotive industry as they relate to manufacturing. She joined IndustryWeek in 2015 as a staff writer covering workforce issues.

Prior to IndustryWeek, Laura reported on the healthcare industry and covered local news. She was the editor of the Chicago Journal and a staff writer for Cleveland Scene. Her national bylines include The Guardian, Slate, Pacific-Standard and The Root.

Laura was a National Press Foundation fellow in 2022.

Got a story idea? Reach out to Laura at [email protected]

Dennis Scimeca

Dennis Scimeca is a veteran technology journalist with particular experience in vision system technology, machine learning/artificial intelligence, and augmented/mixed/virtual reality (XR), with bylines in consumer, developer, and B2B outlets.

At IndustryWeek, he covers the competitive advantages gained by manufacturers that deploy proven technologies. If you would like to share your story with IndustryWeek, please contact Dennis at [email protected].

Ryan Secard

Associate Editor

Ryan Secard joined Endeavor B2B in 2020 as a news editor for IndustryWeek. He currently contributes to IW, American Machinist, Foundry Management & Technology, and Plant Services on breaking manufacturing news, new products, plant openings and closures, and labor issues in manufacturing.

Anna Smith

News Editor

News Editor

LinkedIn: https://www.linkedin.com/in/anna-m-smith/

Bio: Anna Smith joined IndustryWeek in 2021. She handles IW’s daily newsletters and breaking news of interest to the manufacturing industry. Anna was previously an editorial assistant at New Equipment Digest, Material Handling & Logistics and other publications.